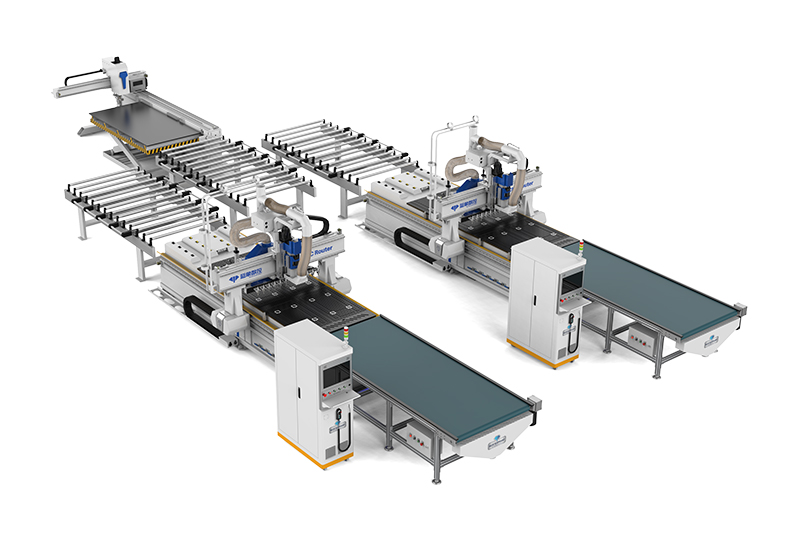

Intelligent Nesting Cell

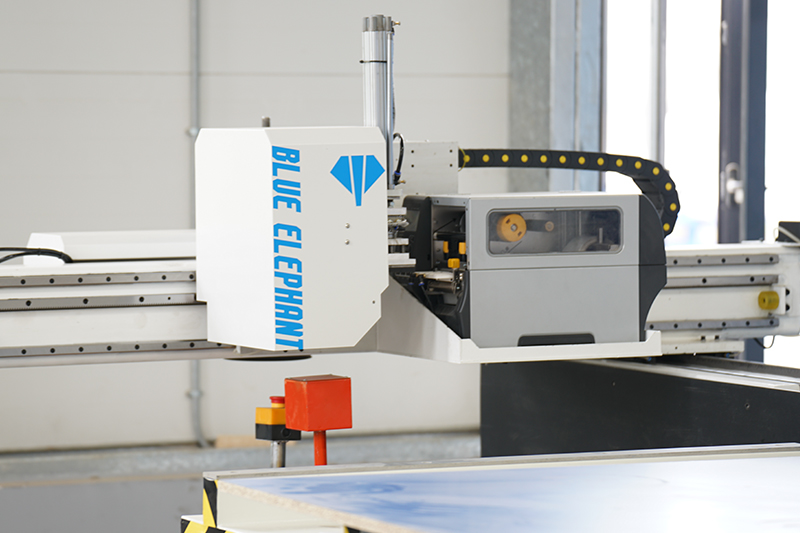

1328 Nesting CNC Router

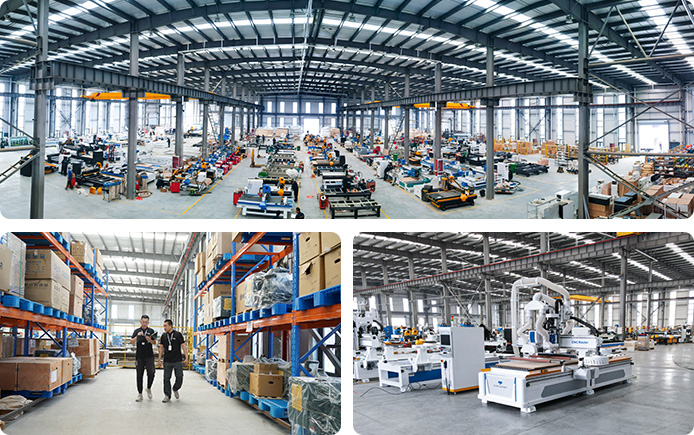

The automatic nesting cell is one of the intelligent nesting solutions in the automatic production line of panel furniture. It combines the labeling system, nesting CNC router, and various auxiliary equipment. So the nesting cell can minimize manpower and improve material yield, enabling massive and customized production.

This nesting cell consists of a high-speed automatic labeling machine, two automatic loading and unloading ATC nesting CNC machines, a power drum line, and a central control system. Operators only need to put the wooden boards on the lifting platform. Then the labeling machine will automatically label the board, and then the central control system will automatically assign it to the nesting center to for cutting.

Optional robot system can be selected for completing the work of palletizing, utilization of residual materials, and waste output.

1. The central control system has the function of optimizing cutting program, which saves time and reduces the waste of plates. At the same time, it supports to supply plates on-site without making files and importing data for one single plate. The processing volume reaches about 240 panels in 8 hours.

2. With simple operation, common workers can operate the nesting cell. The operator just needs to copy the processing program into the central control system and start the machine without operating each machine.

3. The processing of wooden boards placed under the same order is optimized and advanced quickly, improving efficiency and bringing considerable benefits.

4. This nesting cell can be operated continuously among several shifts, which reduces the manual restrictions and standby time.

5. It effectively reduces production errors and material damage caused by human operation.

6. It is more convenient to monitor the whole production process.

Click for details

Nesting cell

Control system

Laneling machine

Power rollers

Click for solution

Click for quotation