“I am a manufacturer of automotive interior finishing, I would like to know what processing advantages of

oscillating cutter compared to rotary knife and laser cutting machine when dealing with flexible materials. I used a rotating knife before, and the processing effect was not good. Later, I switched to laser cutter processing. However, because the heavy smell, it is forbidden to be used by the environmental protection department. From my friends, i know our company produces oscillating cutter. Can you introduce me to this machine?”

This is a friend who made a car interior to send me these message by email. Today, i will introduce for us why we choose the oscillating cutter to process flexible materials from this question by email.

We all know that the processing of flexible materials is mainly through three methods like rotary knife, laser cutting machine, and

oscillating cutter.

The old rotary knife cutter cuts the material by rotating the cutter head at high speed and completes the machining requirements through software drive. The biggest advantage is that the price is relatively cheap. But it has two disadvantages. Firstly, there is a big error in the processing of thicker materials, such as a 1.0 meter pattern, which will become 2-4 cm larger. Second, a large amount of debris will be generated during the processing, which is not good for the operator and is not easy to clean.

Compared to the rotating knife cutter, when process the flexible materials, the cutting surface is very good, clean and smooth by laser cutting machine. However, the maintenance cost of the laser machine is relatively high. Moreover, since when the laser cutter works with the high temperature, there is a great chance of leaving a yellow-yellow mark after cutting the fabric. Another disadvantage is that the smell is very heavy and the environmental protection department prohibits use.

Next, let's talk about the oscillating cutter.

When the oscillating cutter works, it will vibrate up and down, and it will vibrate tens of thousands of times per minute. It is similar to the principle of the saw blade, but it has no serration and no powder. Moreover, the cutter head can be freely changed according to different materials processed. The processed products are also very delicate, the edges are smooth, and the pieces are accurate in size, odorless and environmentally friendly. The cutting speed is twice that of a rotating knife and twice the laser cutter. Therefore, it is also the first choice for many enterprises.

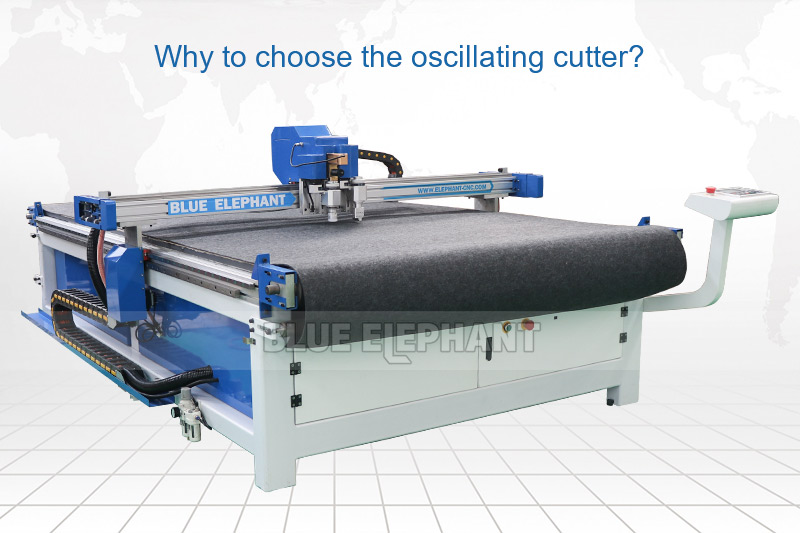

The oscillating cutter provided by Blue Elephant can help you solve more cutting problems more intelligently, accurately and comprehensively. Here are some specific processing advantages for your reference.

- The cutting speed is up to 2000mm/s, which greatly improves the production efficiency. The processing efficiency of one cutting machine is equivalent to 10 workers.

- Cutting precision reaches 0.01mm, and the improvement of precision can maximize product quality and competitiveness.

- Intelligent processing. Automatic cutting can be done by simply entering the graphic to the computer.

- It can be customized according to different processing needs, free to choose CCD camera, projector, double cutter head, double gantry, working area, etc.

If you want to learn more information about Blue Elephant

oscillating cutter, welcome to leave message for me about what you want to know.