1324 CNC Granite Engraving Router

CNC Granite Stone Engraving Machine

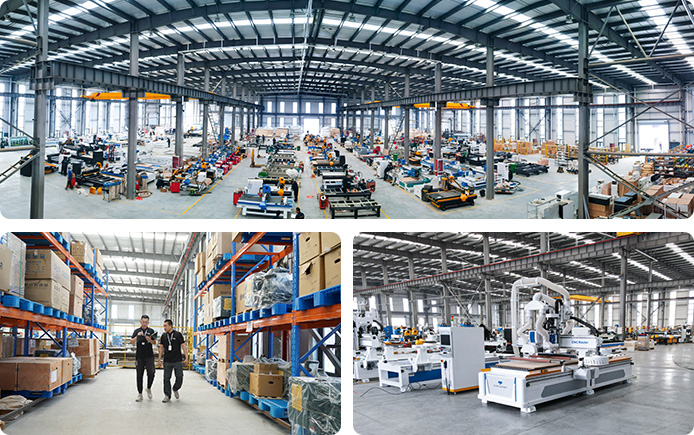

CNC stone carving machine is mainly for stone/granite/marble engraving and carving. Stone CNC has CNC kit of water cooling spindle, which has the advantages of better cooling, high speed & accuracy. It is a popular stone machine for stone/marble engraving & carving.

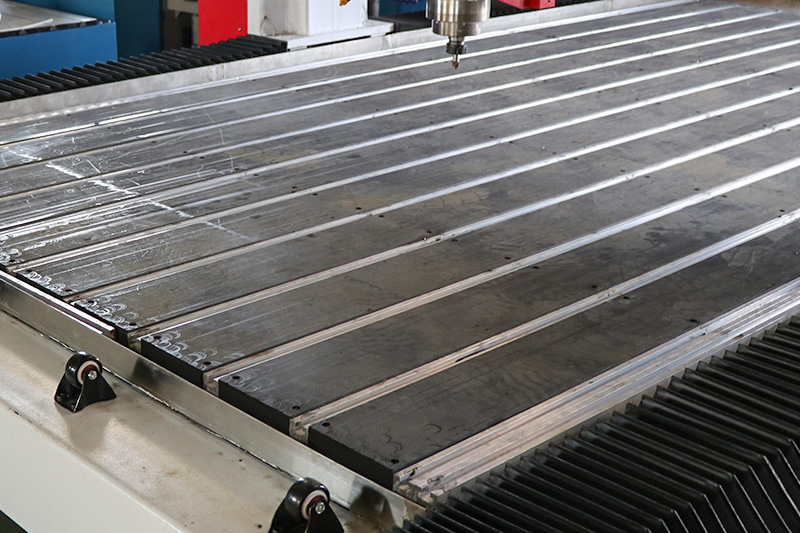

1. CNC stone engraving machine has a heavy-duty steel table, very durable, and stable, strong enough to hold heavy stone/marble/granite, and engraving or cutting it;

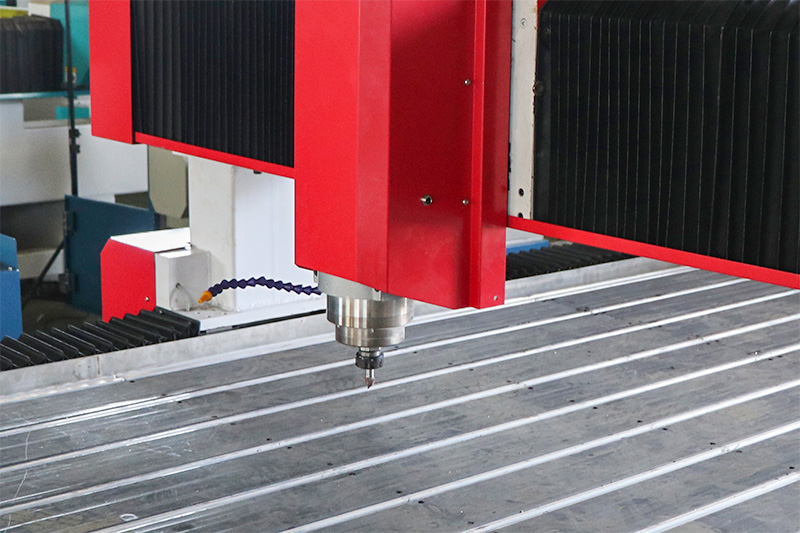

2. Stone engraving machine has CNC kits of a powerful water cooling spindle, perfect working for stone;

3. It has a DSP A11 controller, hand-held, no need connecting to a computer and it is easy to operate; when engraving or carving stone/marble, you'll find it is very convenient, esp for beginners;

4. All parameters and accessories can be customized according to processing requirements, you can choose different CNC kits for this stone engraving machine with the help of our sales manager;

CNC Stone engraving machine is a CNC stone router, we also call it CNC marble engraving machine, it is good at engraving works on stone/marble, and is also able to carve or cut stones with different bits;

CNC Stone machining center will have a better efficiency on stone carving and cutting, if you have a lot of need on carving and cutting, and want to work high efficiently, considering a stone machine center.

| Model | ELECNC1530S |

| X,Y axis travel | 1500x3000mm |

| Z axis travel | 200mm, option: 300mm, 400mm, 500mm, etc |

| Spindle type | 4.5kw water cooling spindle, ER25 |

| Inverter type | 5.5kw |

| Tool magazine | Not included |

| Tool holder with collet | ER25, collet: φ4, φ6, 1/8, 1/2 |

| Control system | DSP A11 handle controller, Option: NK105 |

| Driving system | Stepper motor FL118 bigger mode and Leadshine DM1182 option: Leadshine 750w Hybrid easy servo motor |

| Reducer | Not included, optional Japan Shimpo |

| Machine structure | Heavy duty body with quenching treatment |

| Work table | Aluminum T-slot & vacuum work table |

| Positioning cylinder | Option: 5 pieces (X2, Y3) |

| Linear guide | Taiwan linear guide, 25mm |

| Transmission | X,Y, Z axis: Taiwan TBI high precision ball screw |

| Lubrication system | 1.5L automatic lubrication system |

| Tool calibration | Easy tool sensor calibration |

| Cables | Germany Igus cables with CE, cUL certificate |

| Compatible software | Artcam, Alphcam, Type 3, Ucancam, Aspire, etc |

| Command language | G Code & M Code |

| Traveling speed | 30m/min |

| Working speed | 0-15m/min |

| Re-positioning accuracy | ±0.03mm |

| System resolution | ±0.0025mm |

| Working accuracy | ±0.03mm |

| Working air pressure | 0.6MPa |

| Working voltage | 220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ |

| Vacuum pump |

|

| Dust collect system |

|

| Air compressor | Piston air compressor, screw air compressor |

| Protection device | Light curtain |

| Spindle type | 9kw ATC spindle (HSK F63),12kw(ISO30,HSK F63)etc |

| Rotary device | Industrial-grade support of rotary devicediameter 200mm320mm. |

Click for details

Spindle

Aluminum worktable

Motor

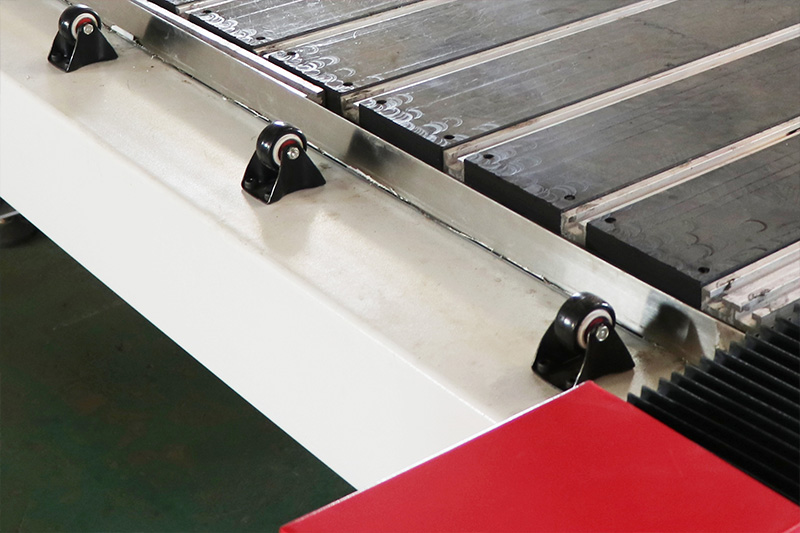

Feeding wheel

Click for solution

Click for quotation