1530 ATC EPS CNC Router

2040 Foam ATC CNC Machine

This is an EPS foam CNC router machine with an automatic tool change for sale. Adopting linear tool changer with 8 tools to realize the processing of complex workpieces at one time, greatly improves processing efficiency.

1. Designed with new type thicker and bigger heavy duty, it ensures that the machine runs smoothly without jitter.

2. Use of dustproof system to ensure good lubrication performance of guide rail and screw.

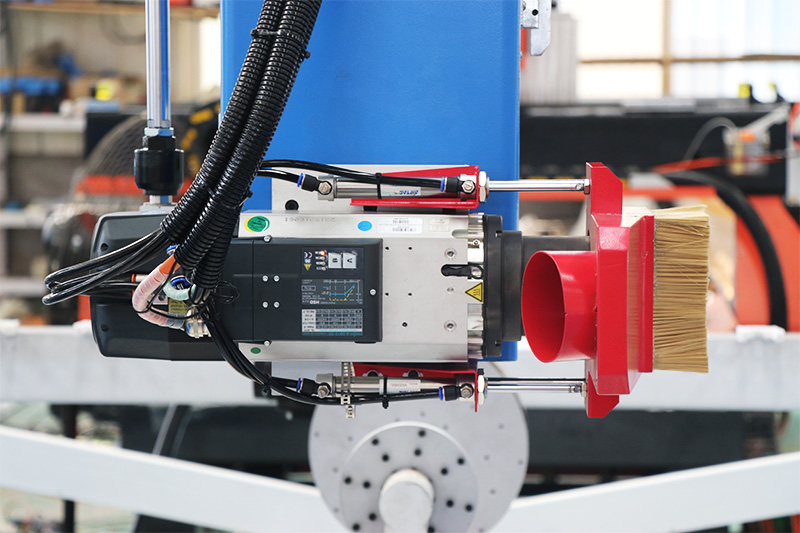

3. Adopting HSD imported air cooling spindle, it has the features of maintenance free, fast speed, and long service life.

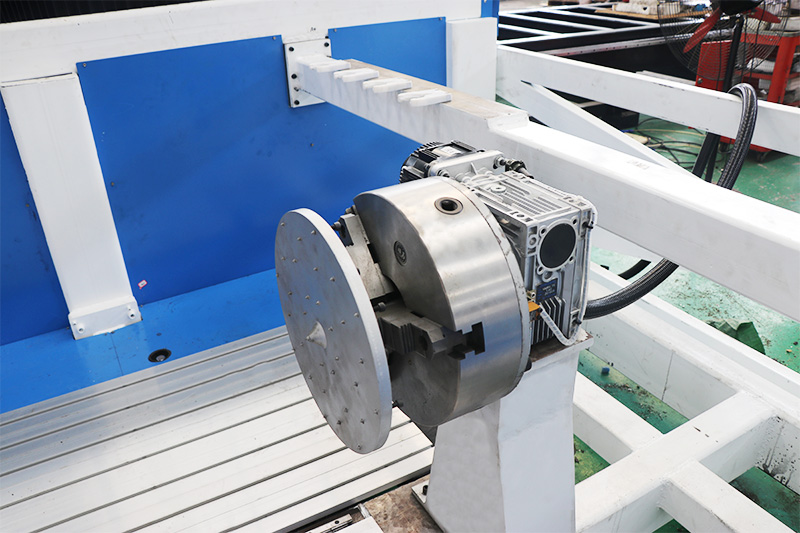

4. Equipped with Yaskawa servo motor and driver with Japan Shimpo reducer to ensure high speed and smooth operation.

| Model | ELECNC1824-4 |

| X,Y axis travel | 1800x2400mm, option: 1500*3000mm; 2100*3000mm; 2100*4000mm, etc |

| Z axis travel | 1200mm, option: 800mm, 1000mm, etc |

| Spindle type | 9.6KW Italy original HSD ATC air cooling spindle |

| Inverter type | 11kw |

| Tool magazine | Linear type auto tool changer Option: Carousel type auto tool changer |

| Tool holder with collet | ISO30, ER32 collet: φ4, φ6, 1/8, 1/2 |

| Control system | Syntec 21MA |

| Driving system | 1.3KW YASKAWA servo |

| Reducer | Japan SHIMPO reducer |

| Machine structure | Heavy duty body with quenching treatment |

| Work table | Aluminum T-slot vacuum work table |

| Linear guide | Taiwan linear guide with dust proof |

| Transmission | X,Y axis: Taiwan / Germany Helical Rack and Pinion Z axis: Taiwan TBI high precision ball screw |

| Lubrication system | Manuallubrication system |

| Tool calibration | Manualtool sensor calibration |

| Cables | Germany Igus cables with CE, cUL certificate |

| Compatible software | UG, Power-mill, Artcam, Type 3, Ucancam, Aspire, etc |

| Command language | G Code & M Code |

| Traveling speed | 60m/min |

| Working speed | 0-45m/min |

| Re-positioning accuracy | ±0.03mm |

| System resolution | ±0.0025mm |

| Working accuracy | ±0.03mm |

| Working air pressure | 0.6MPa |

| Working voltage | 220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ |

| Dust collect system |

|

| Air compressor | Piston air compressor, screw air compressor |

| Protection device | Light curtain |

| Spindle type | 9kw ATC spindle (HSK F63), 12kw (ISO30, HSK F63), etc |

Click for details

Spindle

Rotary device

Towline

Auto lubrication system

Click for solution

Click for quotation