We all know that the nesting CNC routers are very popular in the furniture production line industry. Whether you are making cabinet doors or cabinet bodies, you cannot do without a CNC nesting machine. But different types of nesting CNC machines have different processing functions and their own suitable production. No matter if you are a new user who is going to buy a nesting CNC machine or an old user who intends to replace the production equipment. You must not miss this article.

The following are 8 different types of nesting CNC machine recommendations:

The non-porous process nesting CNC machine is a multi-function cutting machine. This type of nesting CNC machine can do for conventional three-in-one process production. And it can also do for grooving crescent-shaped connectors. It has a wide range of applications. The non-porous process nesting CNC machine is matched with the edge banding machine and the CNC six-sided drill, which is suitable for the customized production of high and middle-end panel furniture. It has a good development prospect. And it is a good choice for customized furniture factories.

The nesting CNC machine with a drilling package is a CNC cutting machine with higher performance. This machine can realize the cutting, drilling, slotting, and other processing techniques of panel furniture. This model can complete ordinary three-in-one cutting and perforation. And it also can open crescent-shaped holes. Besides that, it can meet the requirements of modern panel furniture without holes. Therefore, its use not only improves the production and processing accuracy and efficiency of panel furniture.

And it also saves production costs. The non-porous process belt-row drill bag is equipped with a fully automatic edge banding machine, a side hole drilling machine, software disassembly, and a computer control system. All these can realize automatic production of panel furniture, save labor costs, and improve economic benefits.

The four-process nesting CNC machine is a cost-effective machine. This type of nesting CNC machine is equipped with four spindles, and different spindles can realize accurate cutting and drilling. Therefore, making the production of panel furniture smarter, more efficient, and less labor-saving.

The nesting CNC router with two saws is suitable for panel furniture, solid wood furniture, solid wood composite doors, and other industries. The sub-saw can quickly realize cutting, trimming, and other functions. The automatic tool change spindle can complete processing procedures such as punching, engraving, and milling. Therefore, it can effectively improve processing efficiency.

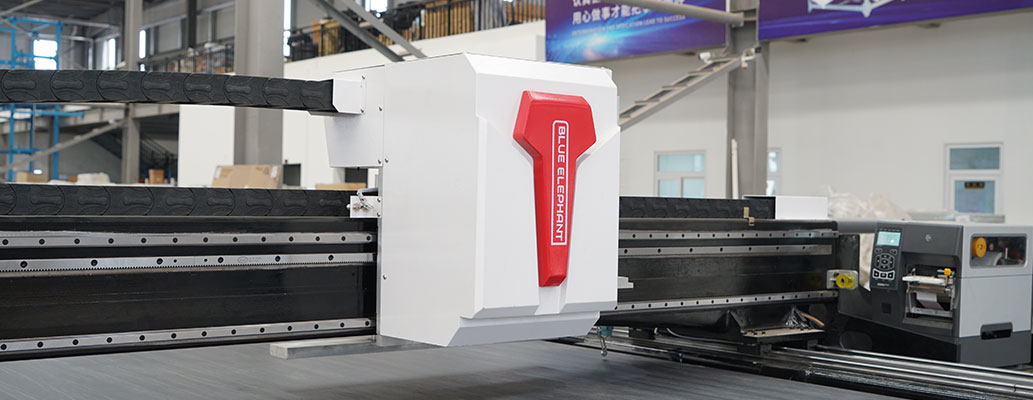

The double-station nesting CNC router processing center is suitable for the production of panel furniture, cabinet doors, closet doors, sliding doors, soft bags, office furniture, wooden doors, solid wood doors, solid wood doors, composite doors, paint-free doors, etc. It is a good choice for furniture production. As the name suggests, the nesting CNC cutting machine is a special machine for cutting with numerical control equipment. It is mainly for whole house custom furniture in the panel furniture industry. It can complete the blanking, slotting, punching, and other work of the board. With intelligent order splitting software, it saves labor and material saving in custom-made furniture cutting. And it can also make special-shaped cutting. The advent of nesting CNC machines allows domestic custom furniture companies to achieve smarter control, reducing personnel costs and material control costs.

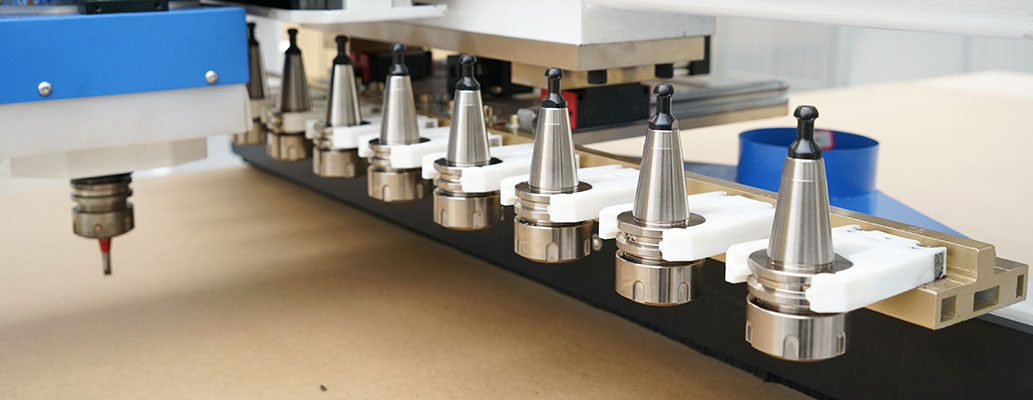

The linear ATC CNC nesting router machine is a woodworking CNC machine. And it is common for the production of panel furniture, cabinets, wardrobes, and carved cabinet doors. This type of nesting CNC router can cut plates, drill holes, draw grooves, cut materials, and do fine engraving. Compared with the previous panel saw, the cutting section is smoother without burrs. It can process block-shaped panels, and can also cut special-shaped panels, such as blanking of panels with missing corners or arc shapes. Therefore, this type of nesting CNC router machine is also particularly suitable for the production of customized furniture in the whole house.

This type of nesting CNC router can automatically push the plate from the processing table after processing with a material pushing device. So it is convenient for the operator to take the material. And it can also realize optimized layout, save time for slow work, and improve production efficiency. With a vacuum adsorption table, it can process different shapes of plates. Therefore, this type of nesting CNC machine can simultaneously complete automatic feeding, vertical punching, rectangular cutting, special-shaped cutting, slotting, automatic blanking, and other processing techniques.

This type of CNC nesting machine can recognize the plate in advance and automatically pastes the corresponding barcode on the plate with an automatic labeling function. Therefore, this nesting CNC router has the characteristics of high precision. As we all know that this type of nesting CNC machine can realize the functions of automatic feeding, automatic labeling, front vertical drilling, slotting, special-shaped processing, and automatic loading and unloading. Equipped with design and order splitting software, optimized typesetting, intelligent control, very simple operation, high processing accuracy, reduced labor costs, and improved production efficiency.

The above is the machine introduction and feature introduction of the most popular nesting CNC machine and the corresponding machine recommendation. After reading the introduction of the nesting CNC machine above, do you know how to choose the right nesting CNC?

Firstly, we should decide whether you are doing door panels or cabinets, or both door panels and cabinets.

Secondly, if you only make cabinets, you can choose a four-process nesting CNC router or a double-spindle row drill pack nesting CNC router. If you do door panels, the tool change machining center is an ideal choice. Due to the different patterns on the door panels, different types of tools are needed to meet the processing requirements. Generally, simple door panel modeling may need 4 knives to complete. If the door panel shape is more complicated or it is a row of panels, which may require 6-8 knives. Therefore, a tool change machining center with an independent tool magazine is the best choice for door panels.

For all door cabinets, you can choose a tool-changing machining center or a drilling package machining center. The tool magazine of the machining center can hold 12-16 tool knives. Generally, only 4 tool knives can make the cabinet, and the remaining carved door panels are also sufficient. The drilling package processing center is to add a row drilling package on the basis of the processing center. Therefore, the efficiency of the cabinet body is higher when the cabinet body is punched, and the cabinet body is made faster.

Thirdly, we should consider that the cabinet needs a nesting CNC machine, a side hole drilling machine, and an edge banding machine. Equipped with a small special-shaped edge banding machine. If you do door panels, you need a machining center and a vacuum press machine, a hinge drill, and a sanding machine.

The nesting CNC machine can realize the functions of automatic slotting, automatic reaming, automatic cutting, and automatic pushing of furniture plates. Because of its high degree of automation, good processing accuracy, and special-shaped cutting, it is popular among the production of panel furniture, whole-house customization, plastic door panel production, table, chair, door and window production, and other industries.

As a professional CNC nesting machine manufacturer, the above machines are the 8 most popular machines among many customer groups. If you don’t know how to choose the nesting CNC router machine, you can leave a message to tell us your specific processing needs and budget. We have a professional team that will tailor a nesting CNC machine that is most suitable for you according to your requirements.