CNC bits play a vital role in modern manufacturing. Whether engraving, cutting, milling, or drilling, CNC bits are critical tools for precision machining. However, selecting the right CNC bits, and using and maintaining them properly can be a challenge for many. In this blog, I'll give you the ultimate guide to CNC bits, making it easy for you to master the technology and apply it to your manufacturing projects.

What are CNC bits?

CNC bits, also known as CNC router bits or CNC cutting tools. They are specialized tools used in CNC machines for cutting, shaping, and carving various materials with precision. CNC bits are typically made from high-speed steel (HSS), solid carbide, or diamond, depending on the specific application and material being machined. Moreover, CNC bits come in a wide range of shapes, sizes, and cutting edge geometries to accommodate different cutting tasks and materials.

What are the different types of CNC Bits available?

| End Mills |

| Router Bits |

| V-Bits |

| Spiral Router Bits |

| Compression Bits |

| Straight Flute Bits |

| Drill Bits |

| Specialty Bits |

End Mills

End mills are versatile cutting tools with a cutting edge on the end. They come in various configurations, such as square end mills (for general milling), ball-nose end mills (for 3D contouring and curved surfaces), and corner radius end mills (for rounded corners).

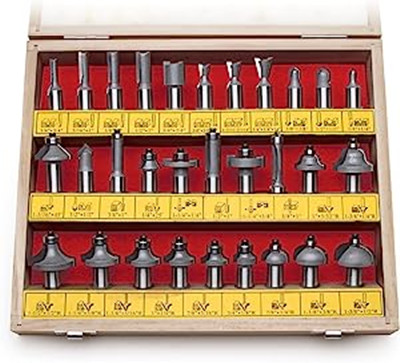

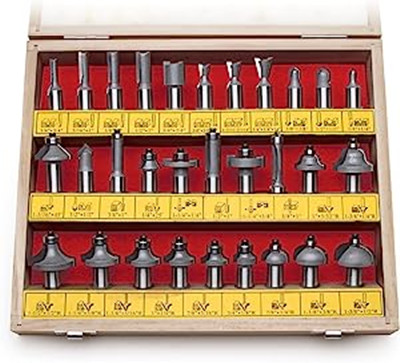

Router Bits

Router bits are primarily used in CNC routers for woodworking applications. They come in a wide range of profiles, including straight bits (for straight cuts and grooves), flush trim bits (for trimming edges), chamfer bits (for creating beveled edges), and round-over bits (for rounding the edges of boards).

V-Bits

V-bits have a V-shaped cutting edge and are commonly used for engraving, sign-making, and carving intricate designs. They come in different angles, allowing for various depths and widths of cuts.

Spiral Router Bits

Spiral bits have a spiral-shaped cutting edge that allows for efficient material removal. They are suitable for plunge cutting, mortising, and routing grooves. Up-cut and down-cut spiral bits are available, each having its advantages for chip evacuation and surface finish.

Compression Bits

Compression bits feature a combination of up-cut and down-cut flutes. They are commonly used for cutting laminates and veneered materials, reducing chipping on both the top and bottom surfaces.

Straight Flute Bits

Straight flute bits have a straight cutting edge and are ideal for cutting soft plastics, wood, and aluminum. They provide a clean cut and are often used for engraving and slotting.

Drill Bits

Drill bits are used for creating holes in various materials. CNC drill bits are available in different types, including twist drills, step drills, and center drills, each suitable for specific hole sizes and applications.

Specialty Bits

There are various specialty bits designed for specific applications. These include dovetail bits (for creating dovetail joints), raised panel bits (for making raised panel doors), and finger joint bits (for creating finger joints in wood).

How do I choose the best CNC bits for my project?

Choosing the right CNC bits for your project is crucial to achieving the desired results. Here are some factors to consider when selecting CNC bits.

Material

Determine the type of material you will be working with, such as wood, metal, plastic, or composites. Different materials require different types of bits and cutting techniques. Ensure that the chosen bit is suitable for the specific material's hardness, density, and characteristics.

Cutting Operation

Identify the specific cutting operation you need to perform, such as milling, profiling, drilling, engraving, or chamfering. Different bits are designed for different operations. For example, end mills are versatile and can handle various cutting tasks, while V-bits are ideal for intricate engraving work.

Bit Type and Geometry

Consider the shape and geometry of the bit that best suits your project requirements. For example, for general milling tasks, a square end mill or ball-nose end mill may be appropriate, while a chamfer bit is suitable for creating beveled edges.

Cutting Speed and Feed Rate

Consult the manufacturer's recommendations or machining guidelines to determine the appropriate cutting speed (spindle speed) and feed rate for the chosen bit and material. Using the correct parameters ensures optimal cutting performance and surface finish.

Bit Diameter and Length

Select the bit diameter and length based on the specific project requirements and the available workspace in your CNC machine. Smaller diameter bits are suitable for fine detail work, while larger diameter bits can remove more material quickly. Ensure that the bit length allows for sufficient cutting depth.

Bit Quality and Durability

Consider the quality and durability of the CNC bits. High-quality bits made from materials like carbide or high-speed steel tend to last longer and provide better performance than lower-quality alternatives. However, higher-quality bits may come at a higher price.

Project Complexity and Precision

Evaluate the complexity and precision required for your project. For intricate or detailed work, you may need specialized bits like V-bits or engraving bits. For high-precision work, choose bits with smaller diameters and tight tolerances.

Budget

Consider your budget and the cost-effectiveness of the bits. While high-quality bits can be more expensive, they often offer better performance, durability, and longevity. Assess the trade-off between cost and performance based on your specific needs and the frequency of use.

How do I install and secure CNC bits in my CNC machine?

Installing and securing CNC bits properly in your CNC machine is essential for safe and efficient operation. Here are the steps to follow:

ensure safety precautions→select the correct collet or tool holder→clean the collet or tool holder→insert the CNC bits→tighten the collet or tool holder→use the correct torque→check for secure fit→perform a test run→monitor and inspect.

1. Ensure Safety Precautions

Before starting the installation process, make sure the CNC machine is powered off and unplugged. Wear appropriate personal protective equipment (PPE) like safety glasses and gloves.

2. Select the Correct Collet or Tool Holder

Check the specifications of your CNC machine and choose the appropriate collet or tool holder that matches the shank diameter of your CNC bit. Collets are typically used for smaller diameter bits, while tool holders with set screws or other mechanisms are used for larger diameter bits.

3. Clean the Collet or Tool Holder

Clean the collet or tool holder and the spindle taper to remove any debris, dust, or residue. Use a lint-free cloth or a recommended cleaning agent.

4. Insert the CNC Bit

Insert the shank of the CNC bit into the collet or tool holder. Ensure that it is inserted fully and securely, following any specific instructions provided by the machine manufacturer.

5. Tighten the Collet or Tool Holder

Depending on the type of collet or tool holder, tighten it securely using the appropriate method. If you have a collet system, tighten the collet nut using a collet wrench. If you have a tool holder with set screws, use an Allen wrench to tighten the set screws evenly.

6. Use the Correct Torque

Ensure that you apply the correct torque when tightening the collet or set screws. Over-tightening may damage the tool or the machine, while under-tightening can lead to tool slippage and poor cutting performance.

7. Check for Secure Fit

After tightening the collet or tool holder, give the bit a gentle tug to ensure it is securely held in place. It should not move or rotate within the collet or tool holder.

8. Perform a Test Run

Before starting a production run, perform a test run or trial cut with the CNC bit to ensure it is properly installed and aligned. This allows you to check for any unusual vibrations, noises, or inaccuracies.

9. Monitor and Inspect

Throughout the machining process, periodically monitor the tool's performance and inspect the bit for any signs of wear or damage. Replace or recondition the bit as needed to maintain optimal cutting results.

How do I maintain CNC Bits to extend their lifespan?

Proper maintenance and cleaning of CNC bits are crucial for extending their lifespan and ensuring optimal cutting performance. Here are some essential tips to help you maintain your CNC bits.

Regular Inspection

Before and after each use, inspect the CNC bits for any signs of wear, damage, or dullness. Look for chipped edges, worn cutting surfaces, or any abnormalities that may affect their performance.

Cleaning after Use

After each use, clean the CNC bits to remove any debris, chips, or residue that may have accumulated. Use a stiff brush, compressed air, or a specialized cleaning tool to gently remove the material from the cutting edges and flutes. Be careful not to damage the bit while cleaning.

Rust Prevention

To prevent rust, it is essential to keep the CNC bits dry. After cleaning, thoroughly dry the bits using compressed air or a clean, lint-free cloth. If required, apply a light coat of rust-preventive oil or a rust inhibitor specifically designed for cutting tools. This will help protect the bits from corrosion during storage.

Dry Storage

Store the CNC bits in a clean and dry environment, away from moisture and dust. Use a dedicated tool holder or organizer to keep the bits organized and protected. Avoid storing the bits loosely, as they can become damaged or dull if they come into contact with each other.

Sharpening and Reconditioning

Over time, CNC bits may become dull or damaged. Consider sharpening or reconditioning the bits to restore their cutting performance. Consult a professional or use appropriate sharpening equipment and techniques to avoid damaging the bits.

Use Proper Cutting Parameters

Ensure that you are using appropriate cutting parameters, such as cutting speed, feed rate, and depth of cut, to prevent excessive wear or stress on the CNC bits. Using incorrect parameters can lead to premature tool failure.

Which CNC bit suppliers are recommended?

Amana Tool

Amana Tool is a renowned manufacturer and supplier of industrial-grade cutting tools, including CNC router bits. They offer a wide range of bit types and configurations to suit various applications.

Freud Tools

Freud is a leading manufacturer of woodworking tools and accessories, including CNC router bits. They have a reputation for producing high-quality precision tools and have a diverse selection of bit profiles.

Whiteside Machine Company

Whiteside Machine Company is known for producing premium-quality router bits, including CNC bits. They have been in the business for over 40 years and are recognized for their excellent craftsmanship and durability.

Onsrud Cutter

Onsrud Cutter is a well-established supplier of cutting tools, including CNC router bits. They offer a comprehensive range of bits designed for different materials and applications, including wood, plastics, and composites.

CMT

CMT is a global supplier of cutting tools and woodworking accessories. They provide a wide variety of CNC router bits, including specialized bits for specific tasks such as joinery, engraving, and trimming.

MLCS Woodworking

MLCS Woodworking is a popular supplier of woodworking tools and bits, including CNC router bits. They offer an extensive selection of bits designed for various woodworking applications at affordable prices.

What are the cost ranges for CNC bits?

The CNC bit cost can vary depending on several factors, including the type of bit, material composition, quality, brand, and the specific supplier or retailer. Here are some general cost ranges for CNC bits.

Entry-Level CNC bit cost

Entry-level CNC bits, often made from high-speed steel (HSS) or basic carbide, can range from around $5 to $20 per bit. These bits are suitable for basic cutting tasks and may have a shorter lifespan compared to higher-end options.

Mid-Range bit cost

Mid-range CNC bits, made from higher-quality carbide or specialized coatings, generally cost between $20 and $50 per bit. These bits offer improved performance, durability, and longevity compared to entry-level options. They are suitable for a wide range of materials and cutting operations.

High-End bit cost

High-end CNC bits, made from premium carbide or with advanced coatings and geometries, can range from $50 to over $100 per bit. These bits are designed for professional use and demanding applications. They offer exceptional performance, extended tool life, and superior cutting results.

Specialty bit cost

Specialty CNC bits, such as those designed for specific materials or specialized applications, may have a higher price range. These include bits for exotic materials, intricate engraving, or specialized profiles. Prices for specialty bits can vary significantly depending on their uniqueness and rarity.