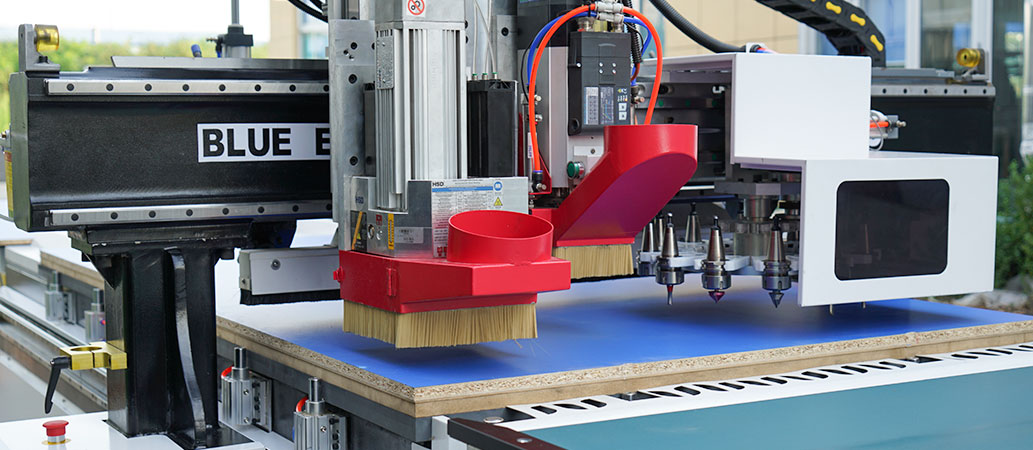

The nesting CNC router is mainly cutting equipment used in the production of panel furniture. The main functions include automatic typesetting, engraving, automatic loading and unloading, special-shaped cutting, vertical punching technology, and other processing techniques.

We all know that the woodworking nesting CNC router is a kind of wood cutting machine. It can realize the processing effects of embossing, flat engraving, and hollow engraving of processed materials. And it has the advantages of fast processing speed, high processing precision, and high processing efficiency.

With other numerical control equipment, the design and production of board furniture such as wardrobes and cabinets can be completed automatically. In addition to the above processing functions, the nesting CNC router is also popular in many other industries. Let's briefly understand what other fields the nesting CNC machine can be applied to?

In this area, the nesting CNC router can engrave various two-color plate signs, three-dimensional billboards, two-color figure statues, embossed medals, organic plate embossments, three-dimensional door headers, etc.

For this model industry, this type of nesting CNC router can make table models, house models, etc.

This type of nesting CNC machine can also make button embossing molds, printing hot stamping molds, injection molds, stamping molds, shoe molds, etc.

It can make the design and production of relief patterns.

Reasonable equipment assembly can guarantee the stability and accuracy of the equipment. And this process cannot be replaced by machinery, for the time being, so only professional and proficient CNC nesting machine assemblers can do it.

After the assembly of each nesting CNC router is completed, one of the key steps is the adjustment and quality inspection of the equipment. Before leaving the factory, each piece of equipment must complete the adjustment of various data and parameters. Every requirement on the inspection form must meet the standard requirements. And the customer should come to the factory to inspect the machine before shipping. Then the machine can be shipped to the customer only after the machine is qualified.

Any machinery will inevitably have mechanical failures under the interference of many external and human factors, and timely after-sales treatment is especially important.

In different processing environments, the nesting CNC router will definitely be subject to various disturbances, such as magnetic field, vibration, ambient temperature and humidity, dust, and other factors. And these external influence factors are different, and their influences are also different.

The working workshop of the nesting CNC router must be clean and tidy. And the equipment must be cleaned and tested before and after to avoid dust falling on the electronic components, affecting the heat dissipation of the equipment and the sensitivity of the contactor. Regular maintenance is a necessary task to maintain the performance of the nesting CNC machine.

Detail 1: The brand and power of the nesting CNC router spindle

The nesting machine needs to cut the material. It is recommended to use a high-power spindle, which has a fast cutting speed and good results. Moreover, the power of the spindle directly affects the processing effect of the product.

Among the many motors used, the stepper motor is the one with lower efficiency (suitable for woodworking engraving machines with lower output). However, there are many manufacturers who want quality and make it reasonable to invest in motors.

And they will choose domestic servo motors (the actual processing speed is less than 8 meters). But from a long-term point of view, considering the service life and actual production benefits, it is undoubtedly the best choice for imported servo motors (the actual empty line can reach 60~80m/min, and the processing speed can reach 15~25m/min).

Speaking of adsorption capacity, we have to raise a knowledge misunderstanding. Many customers think that the suction and clamp dual-purpose table is better and saves electricity during processing. But in fact, its adsorption effect is far less than that of the full adsorption table. In the area of the splint, the cutting process cannot be carried out, and the plate is wasted in disguise.

Moreover, the full adsorption table is actually partitioned, and the non-entire board can be opened with a single adsorption area to achieve the purpose of saving electricity (generally, the partition of the nesting CNC router table is a six-zone design of the table structure).

Now that we have mentioned the adsorption table, we have to talk about the vacuum pump. There are two types of vacuum pumps such as air-cooled and water-cooled. Generally, imported air-cooled vacuum pumps have higher suction power, but the price is generally too high, and the actual cost performance is not high.

The domestic water-cooled vacuum pump is less noisy than air-cooled and has greater suction. However, the use of water-cooled vacuum pumps in areas with lower temperatures needs to pay attention to the problem of antifreeze (usually clean water or add antifreeze every day). Therefore, we can choose a suitable vacuum pump according to your actual needs.

What many manufacturers and customers often overlook is the importance of the frame structure of the bed, because the frame of the nesting CNC router and ordinary woodworking engraving machine is basically similar to those who are not engaged in production and processing.

But in fact, the bed is the basis of the entire equipment, which implies many neglected details. When the motor of the nesting CNC router machine is running, the speed is very fast. In order to ensure that it does not shake during the processing, a bed frame with both stability and timeliness is required.

This requires manufacturers to have very strong machining capabilities and professional processing personnel (excellent manufacturers will generally be equipped with dedicated five-face milling equipment for this treatment).

If the bed is not heavy enough to produce jitter, it will directly affect the accuracy of the processing. Therefore, it can affect the quality of the product. Especially for the 6-meter-long double-station CNC nesting machine equipment, if it is processed by a manufacturer with strong technology, it is impossible to observe the presence of welding points on the bed with the naked eye. In contrast, with equipment with inadequate processing technology, as the use time increases, a series of technical defects will appear, and various problems will gradually appear during use.

Do most customers think it is just some software and a system? Why is there so much difference? But what we need to understand is that CNC equipment is not just a single software that can run. Different functions and different configurations require system coordination and control.

Therefore, systems with different degrees of pros and cons are like systems with different degrees of quality. The computer is the same, it may run the same, but with the increase in usage and the different styles of dismantling orders, a series of problems such as crashes, processing errors, garbled codes, and freezes will occur in the system, which not only delays production and maintenance.

It's also very troublesome to get up. The more professional the manufacturer, the more high-end control system will be used, which not only has fast computing speed but also has good stability, which can fully escort buyers.

Different racks represent different degrees of accuracy and stability. If the meshing degree of the poor quality racks is not accurate enough, the wear resistance is not enough, not only the gantry movement is unstable, but also a lot of noise is generated. The use of a good rack can not only improve the accuracy and the stability of the equipment processing process but also increase the service life of the product.

The X, Y, and Z axes of the nesting CNC machine are equipped with guide rails, and the guide rail is also the most important part of the CNC nesting machine accessories. A high-quality guide rail can not only make the processing process faster, smoother, and more accurate. Moreover, maintenance is also very convenient. With the increase of the number of times of use, the quality of the slightly poorer will not only cause the phenomenon of slipping off, but also the phenomenon that the original set of accessories will become unable to engage after maintenance.

If it is not mentioned here, many buyers or those who plan to purchase will probably not notice it. Cables for such large equipment are not mobile phone charging cables, but only to ensure the flow of current. In long-term mechanical processing, the cable has to go through tens of thousands of bends, and its interior has millions of changes per second. The strength of the signal is interspersed, and the impact of the weather on the strength of the shell must also be considered.

If even a small section of the cable is damaged, the entire device will not operate normally. So the device must be returned to the factory for a new one. Therefore, a good cable must have strong wear resistance, high-temperature resistance, acid and alkali resistance, and high flexibility.

If the CNC nesting machine is used improperly or used for a long time, the following failures will often occur:

Solution: Check whether the mechanical parts are damaged or not firmly installed and whether the rotating parts are moving.

In addition to its own configuration and production process, the performance and service life of the nesting CNC router is also affected by some external factors. Such as the operating method of the cutting machine, daily maintenance, and the processing environment of the factory.

The first is the operation and use of the nesting CNC machine. Operators must go through professional training before they can work because the nesting router machine must be operated step by step when using it. Some details cannot be ignored, and these specific details will be specifically explained during the training, which must attract the attention of the operators. Improper operation may cause machine failure, which will affect the processing schedule and increase unnecessary maintenance costs.

Also pay attention to the daily maintenance of the nesting CNC router machine, use, and maintenance synchronization. Timely and proper maintenance can not only avoid some minor problems in time but also extend the life of the machine in the long run. Keep the table of the nesting machine clean at all times; clean up the dirt on the cutting tools and guide rails in time; lubricate the guide rails and racks regularly; do a good job of dust removal of the motor.

Secondly, the processing environment of the factory will also have a certain impact on the performance and service life of the nesting CNC router. First of all, ensure that the processing environment is tidy and there is no debris near the nesting machine. In addition, if the factory environment is humid, it will cause the opener to rust; too high a temperature can easily cause a fire. Therefore, keep the plant dry and ventilated and avoid direct sunlight.

In addition, if the dust removal work is not done in place, it will also affect the service life of the cutting machine. After using the CNC nesting machine, we must do a good job of dust removal on the table and various parts. Because once the dust enters the inside of the CNC opener, it will cause great damage to the CNC nesting, affect the normal use of the nesting CNC router, and affect production efficiency.

Thirdly, anti-rust work is also one of the main factors affecting the life of the nesting CNC router. Regularly do anti-rust work for the CNC nesting machine. With the long-term production of the machine, the CNC wood cutting machine is prone to rust, which will cause problems such as aging of some parts, and reduce the working efficiency of the cutting machine.

Finally, not paying attention to the lubrication of the transmission device will also affect the service life of the nesting CNC router. Therefore, we must pay attention to the lubrication of the nesting CNC router machine transmission. Because when the CNC nesting machine is running, if the machine's transmission device is blocked, it will cause the cutting machine to feed unevenly. And which will affect the quality of the blanking and have a certain impact on the production.

According to survey statistics, 80% of solid wood furniture companies in the furniture manufacturing industry have adopted CNC woodworking nesting machines as their main processing equipment. With the increasing demand for CNC nesting routers, do you know how to choose a nesting CNC router that suits your processing needs?

First of all, you must be clear about your needs. The furniture manufacturing industry is all-encompassing. And it is divided into many categories of furniture. Before choosing a nesting CNC router machine, you should understand your processing needs. Then we can choose the right cutting machine according to your needs. For example, furniture door panels need to choose a disc tool changer or a straight-line automatic tool changer. The door panel needs a variety of cutter heads for processing, and a fast tool changer is required to improve processing efficiency.

Secondly, we must choose a strong manufacturer. The woodworking nesting CNC router manufacturers have developed to the present, with relatively complete technology. However, there are also many small manufacturers who lack strength. When choosing a nesting CNC router machine manufacturer, we must shop around and conduct on-site inspections when necessary. Of course, after-sales service must also be considered.

Finally, choose a custom nesting router machine. Many wood-cutting machine manufacturers are unable to create products according to the actual needs of customers. Customer needs are diverse. It is difficult to meet different requirements such as the size of wood processing and engraving needs at the same time. This requires you to choose a tailor-made manufacturer to customize the equipment for you. After understanding your specific needs, the manufacturer can build the most suitable equipment for you according to it. And the later processing will surely achieve a multiplier effect.

The above is the relevant information about the CNC nesting machine we talked about. Whether it is about the machine or the parts of the nesting CNC router, as well as the operation, purchase, and maintenance of the nesting machine, this article is helpful to you. In the next article, I will also recommend some popular nesting CNC routers for your reference. Thank you for reading. If you want to know more about the cutting machine or other CNC machines related information, please leave us a message.