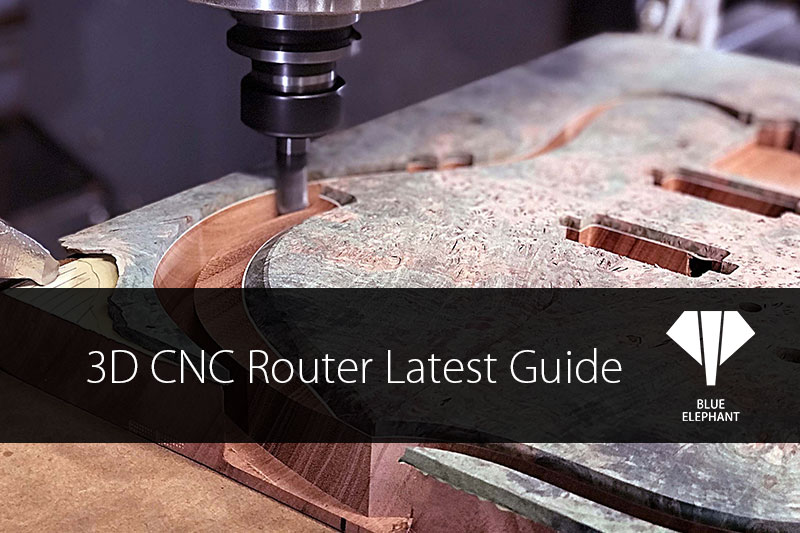

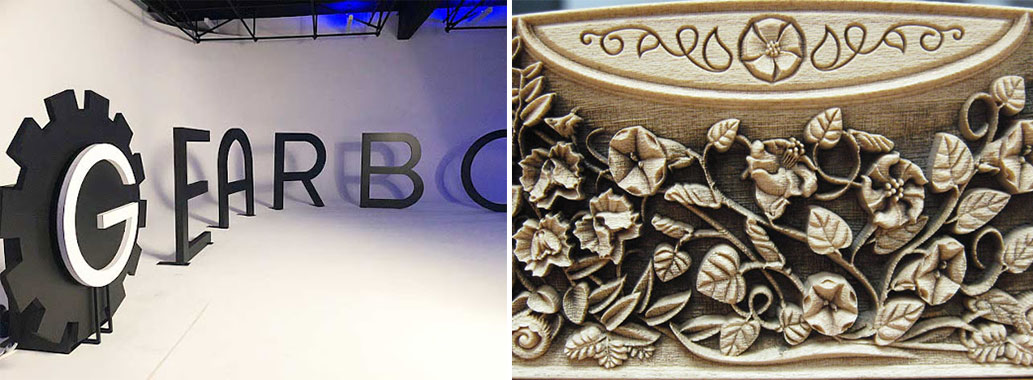

3D CNC Router is the name that recently rises for the CNC router machine which can process three-dimensional workpieces. Compared with an ordinary 3 axis CNC engraving machine, the biggest advantage of the 3D CNC router machine lies in the processing of 3D products. There are plenty of products in our life that can be made by a 3D CNC wood router. For example, 3D advertising signs, artworks, crafts, statues, sculptures, staircase handrails, building columns, etc.

In case that you want to buy a 3D CNC router machine, what basic information you need to know? This article can solve your problem. It lists the basic information, such as the definition, classification, advantages, and applications of the 3D CNC wood carving machine.

What is a 3D CNC router

CNC router is the equipment integrating computer technology and mechanical machining technology. It adopts multiple processing technologies to cut and engrave a wide range of materials, like wood, metal, PVC, glass, plastic, acrylic, etc. The 3D CNC engraving machine is a type of CNC router machine that can process three-dimensional workpieces.

In the broad sense, any CNC engraving machine that can process 3D CNC projects can be deemed as a 3D CNC router. But the processing path is not limited to X, Y and Z three axes. For example, the 5 axis CNC router is a type of 3D CNC router machine, and it can process on X, Y, Z axes and the A and B axes.

The working principle of the 3D CNC wood carving machine is the same as that of the ordinary CNC router. We use CNC router software to convert our CNC router ideas into G codes that the CNC wood router could understand. And the control system controls the automatic movement of the three or four axes to complete the engraving work.

Types of 3D CNC router

There are three types of commonly-used CNC routers that can process 3D CNC projects. So the common 3D CNC router falls into three categories, namely 4 axis CNC router, rotary axis CNC router, and 5 axis CNC router.

4 axis 3D CNC router

The 3D 4 axis CNC router refers to the 3D wood engraving machine with a rotating spindle. The 4 axis CNC router has the same axes as the 3 axis CNC router plus an additional A axis. This A axis can rotate the spindle around the X-axis up to 180 degrees during the working process.

The 3D 4 axis wood carving machine allows to cut and engrave on multiple sides of the workpiece without resetting While a 3 axis CNC router can only cut and engrave one side of the same piece at a time. 4 axis CNC router machines are the preferred method for advanced, intricate cuts and carvings like those often seen in furniture, musical instruments, cabinetry, and more.

Major configurations of 4 axis 3D CNC router

Different processing needs require different specifications and configurations. The basic configurations include the following:

| Brand |

Blue Elephant |

| Model |

4 axis CNC wood router |

| CNC router table size |

4’x4’, 4’x8’, 5’x10’, other custom sizes |

| Voltage |

220V/380V, 50/60Hz, 3 phase |

| Materials |

Wood, plastic, stone, soft metal, acrylic, ABS, PVC, rubber, crystal |

| Capacity |

2D, 2.5D and 3D machining |

| Control software |

Type3, Ucancam, Artcam, Alphacam, Fusion360, UG, Vectric Aspire, etc. |

| Control system |

Mach3, DSP, Siemens, Syntec, NC-studio, LNC |

The 4 axis 3D wood carving machine price ranges from $5,000 to $15,000. This is just an average price range. The specific 4 axis 3D wood carving machine price relies on the specific specifications and configurations the machine adopts.

The 4 axis 3D CNC wood router has wide applications in wooden furniture, advertising signs, construction, decoration, mold, and other industries. With automatic tool change function, the 4 axis 3D CNC router machine can realize fast and free switching between various types of CNC router tools to complete complex processes.

Rotary axis 3D CNC router

In terms of the machining path, the rotary axis 3D CNC router also machines along 4 axes. But differing from the above 4 axis CNC wood carving machine, its spindle can't rotate and the machining along the 4th axis is realized by an additional rotary device. So the rotary axis 3D CNC router is also called 4th axis CNC router, rotary axis CNC router or 3D CNC router with a rotary device.

Major configurations of 4th axis wood carving machine

| Brand |

Blue Elephant |

| Model |

4th axis CNC router |

| CNC router table size |

4’x4’, 4’x8’, 5’x10’, other custom sizes |

| Voltage |

220V/380V, 50/60Hz, 3 phase |

| Materials |

Wood, plastic, stone, soft metal, acrylic, ABS, PVC, rubber, crystal |

| Capacity |

2D, 2.5D and 3D machining |

| Control software |

Type3, Ucancam, Artcam, Alphacam, Fusion360, UG, Vectric Aspire, etc. |

| Control system |

Mach3, DSP, Siemens, Syntec, NC-studio, LNC |

The 4th 3D wood carving machine price is similar to the 4 axis CNC router, about $5,000 to $15,000. This is also a reference price range. Different choices of CNC router kit and parts will lead to different 3D wood carving machine prices. Generally speaking, the smaller the working size and the simpler configurations, the lower the machine price.

Thanks to the rotary device, the 4th axis 3D wood carving machine is able to engrave workpieces on 360°. So it is quite good at engraving cylindrical 3D CNC projects, such as table and chair legs, columns, pillars, posts, door and bed frames, etc.

5 axis 3D CNC router

The 5 axis 3D CNC router also has three basic axes (X, Y and Z) and at the same time two additional rotary axes — A axis rotating around X axis and B axis rotating around Y axis. This dual-rotating function allows engraving work on five sides of the materials. So the 5 axis CNC router is the 3D CNC router machine in the true sense.

Major configurations of the 5 axis 3D CNC wood engraving machine

| Brand |

Blue Elephant |

| Model |

5 axis CNC router |

| CNC router table size |

1220*2440*1000mm, 3000*5000*1100mm, other custom sizes |

| Voltage |

380V, 50Hz, 3 phase |

| Materials |

Wood, plastic, stone, metal, acrylic, ABS, PVC, rubber, crystal |

| Capacity |

2D, 2.5D and 3D machining |

| Control system |

FANUC, SYNTEC, DMS |

As the 5 axis 3D CNC engraving machine has relatively high processing requirements, its spindle, motor, driver, inverter and other electric parts often adopt high power. And other CNC router kit or parts also use high-quality or imported brand products. With advanced technology and high-quality parts, the 5 axis 3D wood carving machine price is relatively high, ranging from $30,000 to $120,000 approximately.

If your company has enough budget and large productivity and sales volume, the 5 axis CNC router machine will undoubtedly further improve your work efficiency and output. But common small and medium enterprises often can't afford such price. Fortunately, the 4 axis and rotary axis 3D CNC routers can well meet their requirements.

5-axis CNC routers are often used to cut large, three-dimensional parts in the automotive, aerospace, watercraft, furniture, and molding industries.

Advantages of 3D CNC router

Increased effectiveness of production.

High-level automation of the 3D CNC engraving machine minimizes human interference during the machining process. Even for the complex 3D CNC projects that can only be done manually before, the 3D CNC engraving machine can complete precisely at a high speed.

High precision and repeatability.

The 3D wood engraving machine can produce parts with high precision tirelessly. The error between parts is tiny, showing high repeatability. So the 3D CNC wood router is widely used for mass production.

Simplified work and reduced workload.

The operator will spend a lot of time and energy to do the complicated engrave work with traditional machines. Now, this can be programmed by the 3D wood engraving machine, which simplifies the operator's work. One operator can operate two CNC router machines at the same time, saving labor costs.

Flexible processing.

As long as you have good 3D CNC machining ideas, and can turn them into drawings, the 3D CNC router machine can produce the 3D parts you want based on your drawings.

What can a 3D CNC router do

3D CNC engraving machine has wide applications in multiple industries, such as woodworking, stone engraving, metal engraving, etc. Common applications of the 3D wood engraving machine include:

Furniture: wooden doors, cabinets, office and house wood furniture, tables, chairs, doors and windows with complex engraving designs.

Construction & decoration: construction frames, building columns, pillars, posts, cylindrical or square legs, artistic embossed screens, fan windows, embossed craft gifts, etc.

3D statue: wooden, stone, acrylic and plaster statues and sculptures.

Mold: wooden, foam, and metal molds used in various industries.

Jewelry: various acrylic, silver, gold earrings, necklaces, bracelets, rings, and other jewelry.

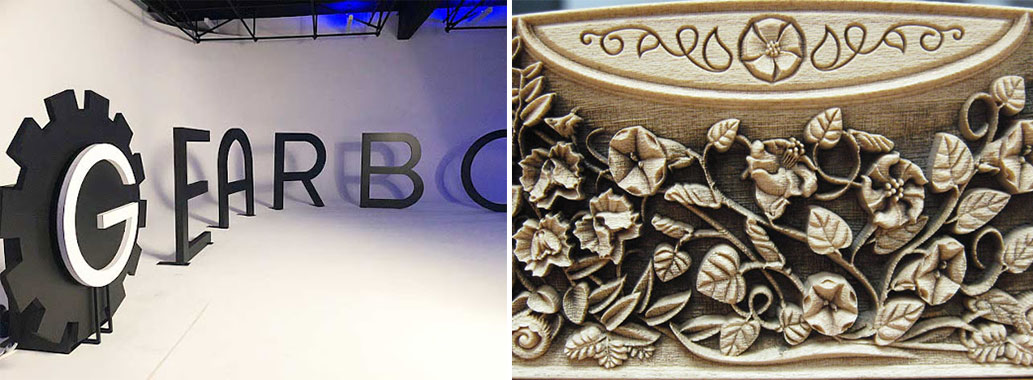

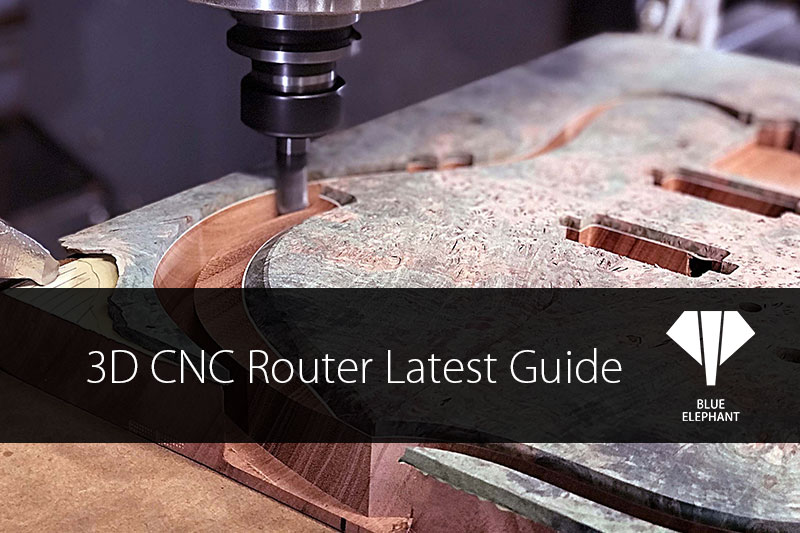

Advertising: wooden signs and letters, acrylic letters and signs, PVC signs and letters, logos, billboards, nameplates, 3D characters and signs, stamps, double-colored plate signs, double-colored 3D human statues, relief medals, 3D nameplates.

Tips for successful 3D CNC machining

The 3D wood engraving machine can complete precise 3D CNC machining. But sometimes, there will be errors or not ideal 3D CNC machining effect. Here are some tips for successful 3D CNC machining:

Select the right 3D CNC router and CNC router bits.

A workman must first sharpen his tools if he is to do his work well. So if you want excellent 3D CNC machining, you must select a good 3D CNC machine and the CNC router bits fitting your work. For how to choose the right CNC router and CNC machine manufacturer, I've mentioned in the previous article. So here let's talk about the CNC router bits.

Most 3D CNC machining requires at least 2 different CNC router bits. The first will be a roughing operation using a fairly large diameter bit. So the majority of the waste material can be removed as quickly as possible. The diameter of the second CNC router bit will determine the smoothness and the amount of detail produced in the finished part. The smaller the diameter, the more details you will see. For extremely complex engraving work, I recommend choosing the 3D CNC wood engraving machine with the automatic tool change function. It can change to 8, 10 or more different CNC router bits very quickly.

Use appropriate software for 3D design and programming.

The quality of the CNC router program has a close relation to the quality of the finished products. Nowadays, there are many powerful CAD and CAM software that is relatively cheap and easy to use. So make sure to choose the right CNC router software for the 3D CNC machining work you are doing.

The commonly used CNC router software includes AutoCAD, Artcam, Fusion360, UG, Vectric Aspire, etc. All such software is good at handling text and can create 3D reliefs from 2D images.

Choose a suitable machining strategy

You can choose among many machining strategies and the best one depends on the type of work you are doing and the capabilities of your CNC router software. The machining strategies mainly include the raster strategy, offset, pocketing or specialized ones such as moulding, v-carving or texture type strategies. Almost always, a combination of strategies will provide the best 3D CNC machining result and the shortest cycle time.

Best 3D CNC router machines for sale

After understanding the basic information of the 3D CNC router, I'd like to introduce the four best 3D CNC router machines from Blue Elephant. Blue Elephant has been committed to the R&D and production of CNC equipment for over 10 years. And its products are exported to more than 130 countries and regions around the world. Both the product quality and after-sales are guaranteed.

Besides, this 3D 4 axis CNC router has an effective working area of 1300x2500x400mm. This custom working area depends on the maximum size of your processing materials. This 3D wood carving machine adopts a vacuum T-slot CNC router table, which is divided into four areas and each of them can be controlled independently. If you're a furniture making manufacturer or engaged in the advertising industry, this CNC router is no doubt a good choice.

This CNC router machine has extensive applications in wood panel furniture making. The rotating spindle enables the 3D CNC wood router to make grooves on the left and right sides of the wooden board. It is suitable for installing invisible connectors to assemble the panel furniture. Except that, by changing to other types of CNC router bits, this machine can realize multiple complex engraving processes.

If required, we can also change the ordinary spindle into a rotating spindle or ATC spindle. So it can process more 3D engraving work.

The 5-axis linkage control system controls this CNC wood router to work on 5 axes, so it's quite suitable to make 3D statues, molds, and models of various materials.

Conclusion

3D CNC routers has extensive use in the engraving of various three-dimensional workpieces. Any CNC engraving machine that can process 3D products can be deemed as a 3D CNC router. For instance, 4 axis CNC router, 4th axis CNC router and 5 axis CNC router. The 3D CNC engraving machine can have different configurations and specifications based on your specific machining demands. So the 3D wood carving machine price varies greatly.

The price of 4 axis and rotary axis 3D CNC routers is about $5,000 to $15,000 while that of 5 axis CNC routers could reach up to $30,000 to #120,000. Therefore, the 4 axis and rotary axis 3D CNC router machine is applicable for small and medium manufacturing companies with small to medium productivity. The 5 axis 3D wood carving machine is more suitable for high-tech manufacturing enterprises with high productivity and sales volume.

In case of any doubts when choosing a 3D CNC wood engraving machine, you can ask us directly. We will recommend a 3D CNC wood carving machine with configurations that best suit your requirements.

The 3D 4 axis wood carving machine allows to cut and engrave on multiple sides of the workpiece without resetting While a 3 axis CNC router can only cut and engrave one side of the same piece at a time. 4 axis CNC router machines are the preferred method for advanced, intricate cuts and carvings like those often seen in furniture, musical instruments, cabinetry, and more.

The 3D 4 axis wood carving machine allows to cut and engrave on multiple sides of the workpiece without resetting While a 3 axis CNC router can only cut and engrave one side of the same piece at a time. 4 axis CNC router machines are the preferred method for advanced, intricate cuts and carvings like those often seen in furniture, musical instruments, cabinetry, and more. Major configurations of 4th axis wood carving machine

Major configurations of 4th axis wood carving machine Major configurations of the 5 axis 3D CNC wood engraving machine

Major configurations of the 5 axis 3D CNC wood engraving machine