Preface

The laser engraver for metal is also called metal laser engraving machine. Compared with traditional engraving machines for metal, the laser engraver for metal has wider application, higher accuracy, and faster speed. Therefore, the laser engraver machine for metal has been welcomed by various industries at home and abroad.

Maybe you want to know more information about the CNC laser metal engraver. Don’t worry. To help you buy your favorite laser engraver for metal, this article will introduce form the following 5 aspects.

What benefits can I get if buying a laser engraver for metal?

Nowadays, more and more metal processing manufacturers choose to use laser engravers for metal to improve production efficiency and output. Because the laser engraving machine for metal (including laser engraving stainless steel, laser engraving aluminum, and laser engraving various metal alloys) has many advantages. Several advantages of laser engraving machine for metal are listed below.

1. Higher efficiency- increased by 91%

The metal fiber laser engraver for sale is equipped with many high-quality laser CNC kits, such as good laser generator, excellent laser cutting head, and sturdy machine structure. Thus it can ensure fast and stable metal engraving. Its engraving speed can be twice that of a CO2 laser engraving machine for metal. In addition, the fiber laser engraver for metal can increase by 91% when engraving thinner metal sheets.

2. Higher energy saving- more than 86%

The photoelectric conversion rate of the laser engraver for metal is higher than that of the traditional metal engraving machine. Thus, it can save more energy and reduce material waste. The overall energy consumption of the fiber laser cutting system is about 3 to 5 times less than that of the carbon dioxide cutting system, making the energy efficiency increase to more than 86%.

3. Higher processing accuracy- doubled

The laser engraver for metal adopts automatic laser positioning. Its accuracy can reach 0.02mm. Non-contact machining also ensures good machining accuracy.

4. Productivity improvement- 5times

The laser engraver for metal can reach the speed up to 140m/min. It is about 3 to 5 times faster than common CNC metal engraving machines. Thus, the laser engravers for metal greatly improve the productivity.

What can a laser engraver for metal do?

1.1 Kitchen appliance

Now, people have higher and higher requirements for the appearance and application of kitchenware. Many kitchenwares are made of stainless steel and aluminum, such as shelves, cabinets, cooking utensils, knives, etc. Therefore, kitchen-related products have a very broad market in the world. In addition, the laser engraving machine for metal can also realize customized kitchenware according to the different needs of customers.

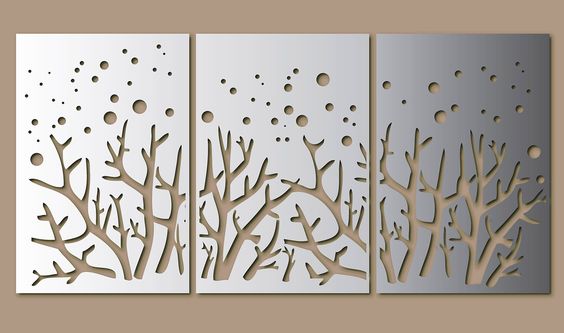

1.2 Decoration industry

The laser engraver for metal has the characteristics of high speed and flexibility, and can quickly engrave many complex graphics. Its carved products are also favored by many consumers. For example, laser engraving stainless steel can make metal hanging lights, and laser engraving aluminum can make some beautiful artworks.

At present, many decorations, which not only have a good-looking appearance but also are not easy to be damaged, are made by the laser metal engraver. Moreover, the laser engraving machine for metal can customize a unique decoration according to your plan. SO more and more people are choosing to use laser engraved metal products to decorate homes, hotels, or other places.

1.3 Model industry

The model industry generally customizes product models according to product characteristics and publicity plans, and many of the materials of this model are made of metal materials. They are generally large in size and exquisite in workmanship, while traditional processing methods are inefficient and not applicable. On the contrary, the laser engraving machine for metal can efficiently produce high-quality laser-engraved metal products and create a unique product model for you.

1.4 Automobile industry

Many metal parts of automobiles, such as doors, exhaust pipes, brakes, etc., can be precisely processed by a laser metal engraver. The manufacture of automobiles requires higher precision and better quality. The metal parts processed by the laser engraving machine for metal have high precision, and the cutting surface is smooth, without the need for subsequent secondary processing.

1.5 Medical industry

With the development of the medical industry and the upgrading of hospital equipment, the market demand for medical equipments has increased rapidly in recent years. Therefore, the high-precision laser metal engraver can laser engraving stainless steel to make lots of medical equipments and surgical appliances.

Metal Engraver VS. Metal Marker VS. Metal Etcher: what are their differences?

Sometimes, people also call the metal engraving near me a metal marking machine or a metal etching machine, because these three can all create permanent marks on the surface of the material. But there are big differences in the marking methods, including the depth of laser engraving and the way of changing. So how do we distinguish between these three types of machines?

Metal engraving machine VS. Metal marking machine

First of all, the laser metal engraver uses the combustion of the laser beam to vaporize a part of the metal surface to achieve the processing effect. The metal marking machine irradiates the laser beam on the metal surface to oxidize it. So that strong color contrast is formed between the oxidized part and the unoxidized part, thereby forming a permanent mark.

Secondly, laser marking metal will not cause any damage to the metal surface. The laser does not engrave the metal, it only marks the surface of the material. While the laser metal engraver will have deeper depths when laser engraving steel and other metal.

Furthermore, the power of the metal marking machine is relatively low. It can only be used to make identification codes, serial numbers, barcodes, two-dimensional codes, etc. However, the power of laser metal engraver is much higher. Because vaporizing metal needs to absorb a lot of energy.

Finally, the laser engraver for metal has a wider range of applications, it can engrave most metal materials. The

metal laser marking machine can only mark some metal materials with small size and low hardness.

Metal engraving machine VS. Metal etching machine

Metal laser engraving machines and metal laser etching machines are very different in working principle, engraving depth, processing materials, processing procedures, and so on.

First, the metal laser etching machine uses the redox reaction between substances to dissolve the metal surface, which is a chemical change. The metal laser engraving machine engraving metal is a physical change. Second, the depth of laser etching metal is relatively shallow. When laser etching metal, only the top layer of the metal is removed, and the metal is not cut. In contrast, metal laser engraving machines cut lines on the metal surface. Third, the metal laser engraving machine is simple to operate and has fewer procedures. However, there are many metal laser etching processes and many details.

How to Choose a Suitable Laser Engraver for Metal?

1. Make clear your processing needs

First of all, it is very important to understand your processing requirements. For example, you should know clearly that what industry you are in, what metal material you want to process, how big the size of the processed material is, and how much thickness you have to wait. These are all important factors in choosing a great laser engraver for metal. If you just want to engrave simple images on metal materials, then a metal marking machine or a low-power laser engraver for metal can meet your requirements.

2. Decided the machine configurations you want

You can preliminarily determine your requirements for machine configuration based on your processing needs. The machine configuration is closely related to the specific processing requirements, so this can also be used as a criterion for your choice of a metal laser engraving machine. Such as spindle, work surface, motor, drive, control system, etc. Generally speaking, the size of the laser engraver for the metal you choose should be able to engrave the largest material you need to process.

3. Confirm your budget

Budget is also very important because the metal engraving machine price varies greatly. While considering machine performance and adaptability, don't forget how much you can afford. Because the metal engraving machine price is affected by many factors. For example, imported or well-known brand kits and parts may bring additional costs to the laser engraver for metal. So before buying, please determine your maximum budget and choose the most suitable machine accordingly.

4. Choose a great brand

There are so many brands of laser engraver for metal on the market, so how do we choose? First of all, the brand is the added value of the product. The value of the brand is reflected in many aspects, such as the manufacturer, the quality of the machine, and the after-sales service provided. If you want to build a good brand, you need good products as the foundation, and only reliable manufacturers can produce good products. Therefore, before buying a machine, we must investigate its manufacturer.

First of all, we have to examine the manufacturers’ R&D capabilities, production capabilities, product quality, and customer reviews. You can get answers from their company website. Secondly, the laser engraving machine for metal produced by Blue Elephant is exported to more than 130 countries and regions. And it has been well received by customers all over the world.

It also has a professional work team and perfect service system. On the one hand, we can provide you with all-day online and offline services; on the other hand, we can solve all problems arising from pre-sales, in-sales, and after-sales. If you have any questions or needs, you are welcome to leave a message or contact us. We will do our best to provide you with the best quality service and the most suitable machines.

Which laser engraver for metal should I buy?

It uses imported roller screws, advanced CO2 laser tubes, and reliable stepping motors. And it can accurately and efficiently engrave stainless steel and other metal materials. The work surface is large, which can satisfy you for engraving large-size metal sheets.

| Description |

Parameter |

| Model |

ELECNC-1325 |

| Working Area |

1300*2500mm |

| Laser Power |

80W/100W/150W |

| Laser type |

Sealed CO2 laser tube |

| Working platform |

Blade platform |

| Position accuracy |

±0.05mm |

The laser engraver for metal adopts imported roller screws, which have the advantages of fast speed, high precision, and stable operation. The laser tube power is available from 40w to 150w, which can meet the diverse choices of users. It can also engrave ultra-high-strength industrial steel sheets to ensure more stable and smooth work. And it is widely used in advertising, handicrafts, decoration, and other industries.

2. Fiber laser engraving machine for metals

This

fiber laser engraving machine is an entry-level and economical laser machine for metal engraving. It adopts an intelligent automatic focusing laser head, which can reach the repeated positioning accuracy at 50μm. And it uses an aircraft-grade aluminum beam, which has corrosion resistance, light weight and high hardness to ensure good engraving stability and accuracy. It is suitable for the development of various laser engraving metal ideas. And it has the advantages of fast engraving speed, long service life, flexible installation, and maintenance-free.

After a series of system optimization, the Blue Elephant fiber laser engraving machine can be used for engraving various metal materials with high hardness and thickness. In addition, it has a wide range of applications such as electronic components, daily necessities, tools, and auto parts.

Fiber Laser Machine Engraves Patterns on the Metal Sheet

Precautions when Using and Maintaining a Laser Engraver for Metal

1. Check the lubricant

Lubricants can reduce friction and damage of parts. Therefore, arranging regular lubricant inspections can extend the life of the laser engraver for metal. At the same time, make sure that you are using good lubricant.

2. Check the focusing lens and reflector

After the focusing lens and the reflector work for a while, the frame of the lens will heat up. And the surface of the lens will become discolored and rusted over time. If necessary, it needs to be replaced if it is peeled off or cracked. In particular, many customers use atmospheric pumps and air compressors, which quickly accumulate water on the focusing lens. So it is necessary to check the cleanliness and quality of the optical path system of the lens on time.

3. Clean the machine

The machine must be cleaned in time after each use. Otherwise, a lot of smoke and dust will not be discharged, which will seriously pollute the lens and laser tube. In this case, the electronic components of the machine are easily oxidized, which will cause poor contact. And if severe, it will also affect the use and accuracy of the machine tool.

4. Keep maintenance records

Keeping correct maintenance records allows you to have the spare tools and parts on hand, thus avoiding extended downtime of the engraver for metal. In addition, maintaining records can avoid accidents and is also important for the safety of operators.

Final Word

After the introduction of the above content, I believe you will have a better understanding of the laser engraver for metal. You must already understand the advantages, the application, the function, and the working principle of laser engraver for metal. And you may have no trouble distinguishing it from the metal marking machine or the metal etching machine.

Later, you will find that laser engraving metal is an interesting process, you can make all kinds of unique patterns on metal. If you are now looking for a good laser engraver for metal, we will provide you with the most timely and high-quality service. And we can also offer you the most suitable laser engraving machine for metal! If necessary, please leave us a message or contact us.