The metal laser cutting machine has stood out from the CNC metal cutting machine with the development of laser cutting technology. As a leading CNC equipment supplier, Blue Elephant is currently committed to providing various models of metal laser cutting machines.

When it comes to Blue Elephant CNC, many customers would think of CNC router machines. Indeed, Blue Elephant CNC router machines are of good quality and reasonable price. And our products have been exported to more than 130 countries and regions around the world. But what we are going to talk about today is the Blue Elephant metal laser cutting machine.

Fiber laser cutting machines are Blue Elephant's major products as well. We have a complete production line for the CNC metal laser cutter, from manufacturing, assembly, quality inspection, testing, to packaging and delivery. This article will take you to look at the metal laser cutting machine types that we provide.

At present, all the metal laser cutting machines provided by Blue Elephant belong to the fiber laser cutting machine. As the name suggests, the fiber laser cutting machine uses a fiber laser source. Its characteristics include a stable light source, long working distance, high efficiency, and maintenance-free, etc. The metal laser cutting machine can cut a variety of metal materials, like steel, stainless steel, carbon steel, aluminum, copper, and various alloys.

Generally speaking, Blue Elephant metal laser cutting machine includes 6 major types. And Each type also has multiple models. All of these metal cutting machines have extensive use in the metalworking industry.

Although the laser metal cutting machine is available in many types, the main function is to cut metal plates or pipes. Laser-cut metal products can be seen everywhere in life. For instance, machine parts, vehicles, mechanical equipment, medical equipment, electrical cabinets, kitchen supplies, metal crafts, etc. Below let me show you the different types of Blue Elephant metal laser cutting machines.

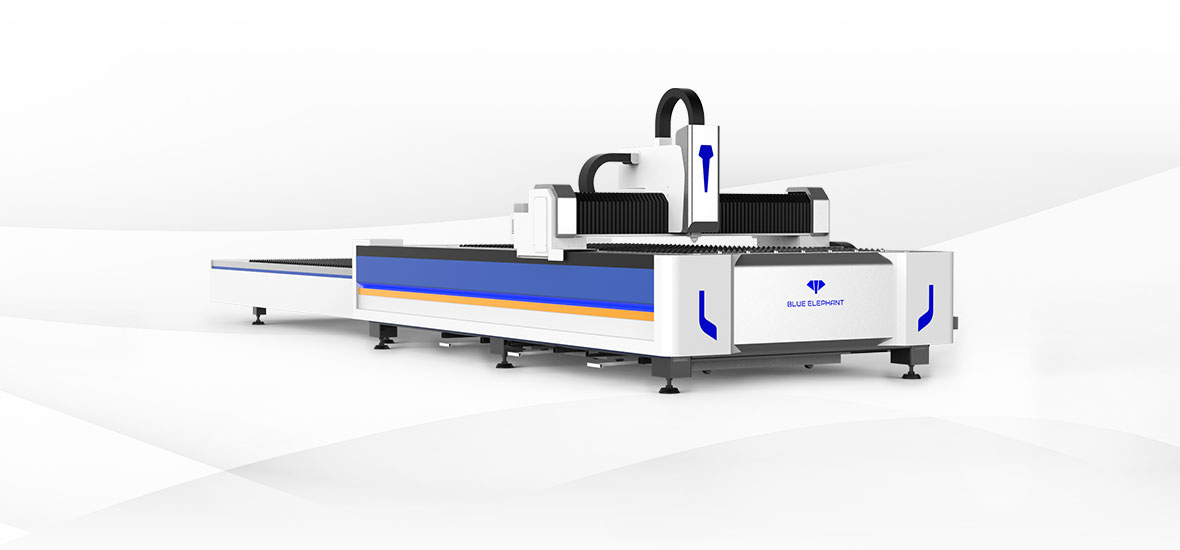

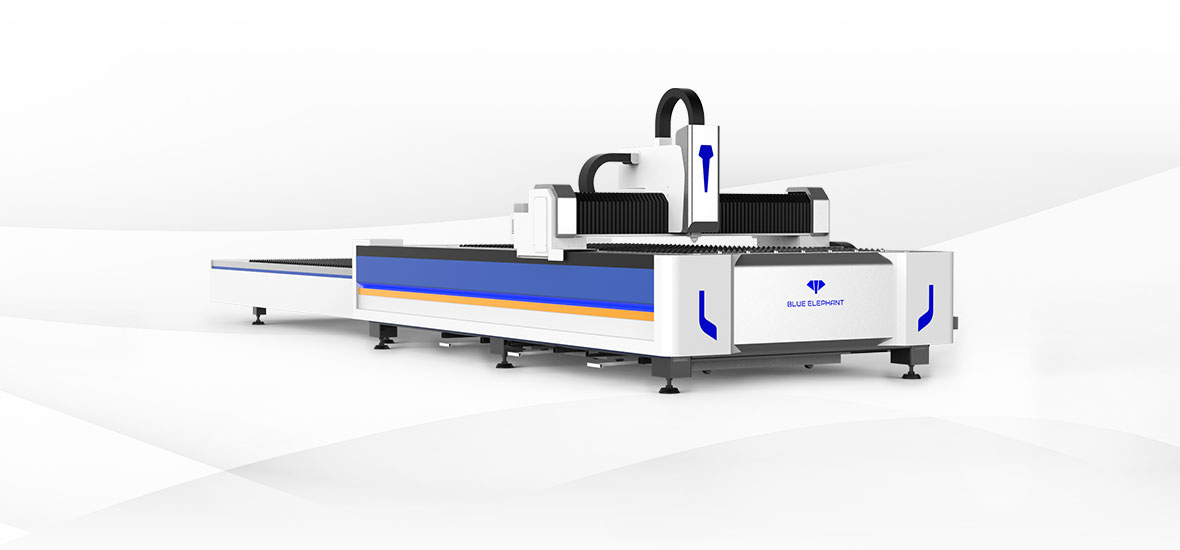

As an entry-level CNC metal cutting machine, it has wide applications and reasonable metal laser cutting machine price. So it is the first choice for the majority of small and medium metal processing companies.

The sheet metal laser cutter for sale adopts an open-type flatbed structure and with a simple design. Operators can load and unload sheet materials from the left, right, and rear sides of the CNC metal laser cutter. Meanwhile, the laser cutter for metal sheets eliminates unnecessary functions and decorations. And it keeps the metal laser cutting machine price at an affordable level.

The minimum processing size of this laser sheet metal cutting machine is 1500*3000mm. It can process most sizes of metal plates. Moreover, you can realize your dream of sheet metal processing without the need for a large workshop. But if you are not on a tight budget and have a large workshop, we also provide larger sizes of sheet metal cutting machines. For example, with the processing area of 2525*6050mm.

Blue Elephant sheet metal laser cutter models

Model

Item |

1530F |

1540F |

1560F |

2040F |

2565F |

| Work area |

1515*3030mm |

1515*4040mm |

1515*6050mm |

2020*4040mm |

2525*6050mm |

| Machine size(L*W) |

4320*2250mm |

5360*2250mm |

7500*2250mm |

7350*2800mm |

5350*3350mm |

| Height (H) |

1950mm |

1950mm |

1950mm |

1950mm |

1950mm |

| Positioning accuracy |

±0.03mm |

±0.03mm |

±0.03mm |

±0.03mm |

±0.03mm |

| Repositioning accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

| Laser |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

| Laser power |

1-4kW |

1-4kW |

1-4kW |

1-4kW |

1-4kW |

| Machine bed |

Tube welded |

Tube welded |

Tube welded |

Tube welded |

Tube welded |

| Laser head |

Raytools |

Raytools |

Raytools |

Raytools |

Raytools |

| Focusing |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

| Lubrication |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

| Support file |

G file, DXF, DWG, PLT, ENG |

G file, DXF, DWG, PLT, ENG |

G file, DXF, DWG, PLT, ENG |

G file, DXF, DWG, PLT, ENG |

G file, DXF, DWG, PLT, ENG |

Video

Here's a video showing the brief installation and cutting process of a 1530 steel laser cutting machine. The former part of the video demonstrates how to connect and install the switch box, chiller, etc. And the latter paper shows the cutting process of carbon steel, brass, aluminum, and stainless steel sheets.

High-efficiency configuration

We provide a double-platform sheet metal laser cutter to pursue highly effective loading and unloading. The two platforms adopt a high-and-low exchanging method, saving loading and unloading time. And the automatic exchange time is about 25s, which improves processing efficiency and saves labor costs. In addition, the driving motor is installed in front, leaving sufficient space for loading and unloading at the rear worktable. For more information about the exchange platform sheet metal laser cutter for sale, please click the picture or

HERE.

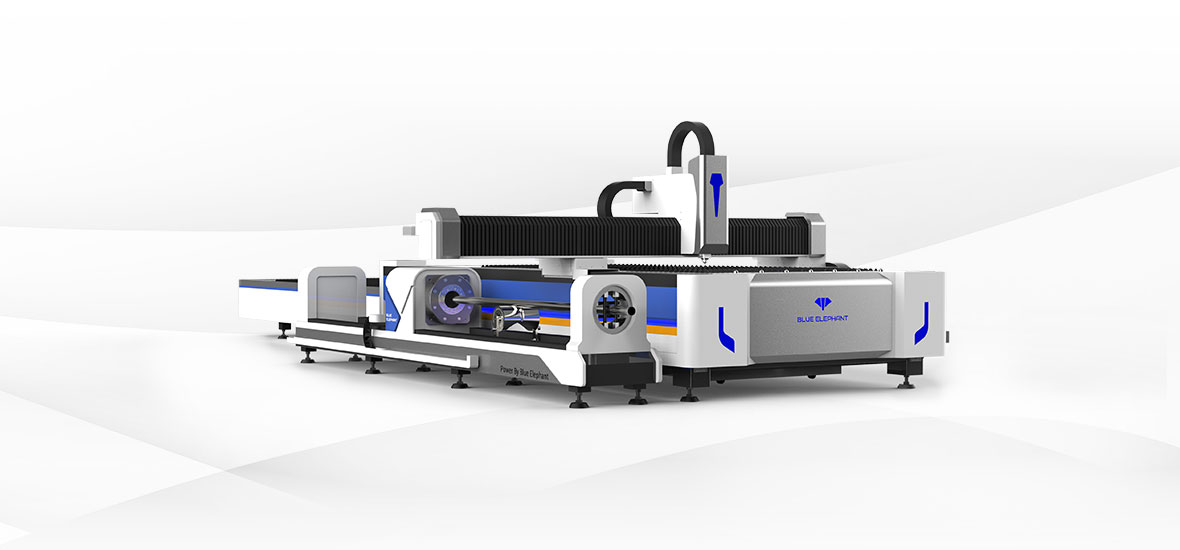

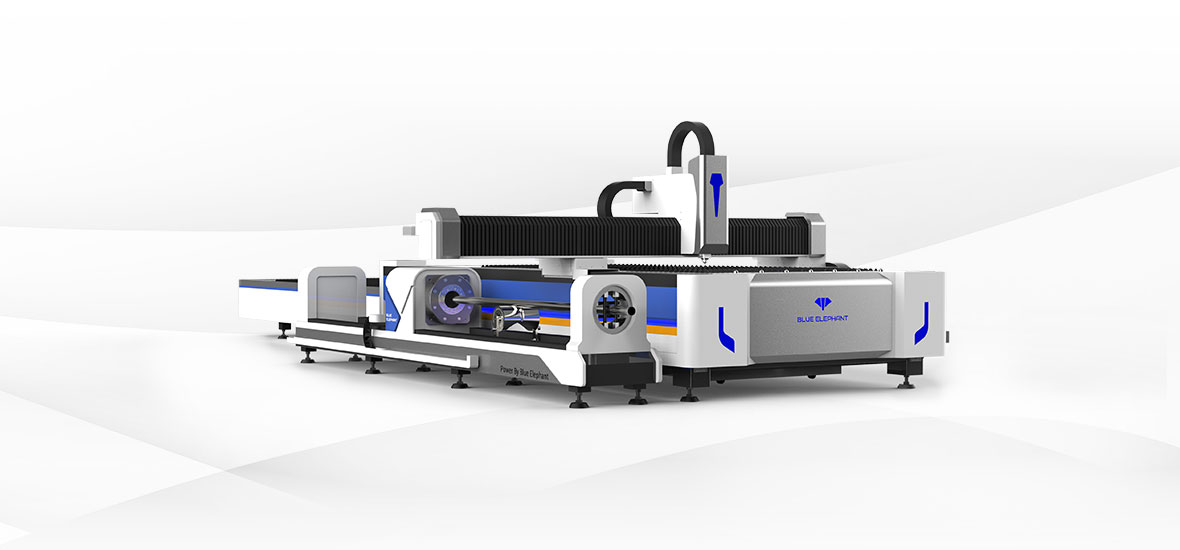

This steel laser cutting machine is good at cutting either regular or irregular pipes effectively and precisely. So, it is quickly applied to various metal processing industries with its professional and stable cutting effect. For example, household appliances, advertising signs, and boards, equipment manufacturing, kitchen supplies, etc.

The tube and sheet metal laser cutting machine equips dedicated CAD/CAM programming and nesting software. It can help save raw materials and maximize the use of materials as well. For optional configuration, you may choose the WIFI control method to connect directly with the CNC system. So you can achieve remote operation and troubleshooting effectively.

The tube and sheet fiber laser cutting machine falls into two parts in terms of structure. The sheet cutting machine part is similar to the above sheet metal laser cutting machine. And the other part is for cutting pipes and tubes. It adopts double pneumatic chucks, whose speed is 3 times the electronic chuck. So this reduces the loading and unloading time greatly. Besides, the chucks can properly secure square, round, rectangular and irregular pipes without damaging their surfaces.

Blue Elephant tube and sheet metal laser cutting machine models

Model

Item |

1530FT |

1545FT |

1560FT |

2040FT |

2060FT |

| Work area |

1515*3030mm |

1515*4545mm |

1515*6050mm |

2020*4040mm |

2020*6050mm |

| Bearing capacity |

800kg |

1100kg |

1500kg |

1300kg |

2000kg |

| Positioning accuracy |

±0.03mm |

±0.03mm |

±0.03mm |

±0.03mm |

±0.03mm |

| Repositioning accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

| Laser |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

| Laser power |

1-4kW |

1-4kW |

1-4kW |

1-4kW |

1-4kW |

| Laser head |

Raytools |

Raytools |

Raytools |

Raytools |

Raytools |

| Focusing |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

| Lubrication |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

| Max. pipe length |

3m/6m |

3m/6m |

3m/6m |

3m/6m |

3m/6m |

To know more parameters or specifications of this tube and sheet metal laser cutter for sale, please

CONTACT US.

Video

This video shows the dual use fiber laser cutter cutting sheets and pipes with different thicknesses and diameters. The cutting materials include carbon steel, brass, and stainless steel sheets, and round and square pipes.

High-efficiency configuration

This metal sheet and tube CNC metal cutting machine can also equip an exchange platform the same as the sheet metal laser cutting machine. This can improve loading and unloading efficiency and save labor costs greatly.

Click to know more details about the exchange platform sheet and tube metal laser cutting machine.

Both above two metal laser cutting machines adopt an open structure. Thus, part of the smoke generated during the cutting process may release into the atmosphere. This could cause certain pollution and impact on the air. It is forbidden in some countries, especially in Europe. Therefore, we launch the full cover models.

Full cover metal laser cutting machines have a fully enclosed protective cover enclosing the machine bed. In this way, operators can observe the whole cutting process outside the cover while keeping their safe.

Except that, the smoke generated from cutting will also be removed by the fume extractor inside the cover. So, this cover protects not only the operator’s safety but also the working environment. The full cover laser metal cutting machine mainly cuts metal sheets and plates, like steel, aluminum, copper, brass, and their alloys.

This CNC laser machine uses an aviation-grade extruded aluminum gantry with light weight, good rigidity, and high precision. It ensures smooth operation and precise cutting of the cutting head. In addition, the control system is integrated inside the machine bed. So, it reduces the failure rate incurred by the disturbance and uncertainty brought by excessive line switching. The metal laser cutter can work more stably.

Blue Elephant provides two models of full cover metal laser cutting machines. One is with two platforms and the other is equipped with an automatic loading and unloading system.

With exchange platform

Basic parameters of the exchange platform full cover laser metal cutting machine

Model

Item |

1530S |

2040S |

2060S |

2560S |

| Working area |

1515*3030mm |

2020*4040mm |

2020*6050mm |

2525*6050mm |

| Bearing capacity |

800kg |

1500kg |

2100kg |

2700kg |

| Table exchange time |

25s |

30s |

35s |

40s |

| Max. acceleration |

2.0G |

2.0G |

2.0G |

2.0G |

| Positioning accuracy |

±0.03mm |

±0.03mm |

±0.03mm |

±0.03mm |

| Repositioning accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

±0.02mm |

| Laser |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

| Laser power |

1-4kW |

1-4kW |

1-4kW |

1-4kW |

You can scan the product page to see other parameters and configurations. Or contact us directly. Besides, the above values are not absolutely accurate and may differ from the actual use.

Video of this fully enclosed CNC metal laser cutter with two platforms

The video displays the cutting of 8mm and 12mm carbon steel and 2mm and 6mm stainless steel sheets.

With automatic loading and unloading system

In case that you have a sufficient budget and larger production needs, this metal CNC machine is indeed a better choice. Meanwhile, the metal laser cutting machine price is relatively high due to the upgraded configuration. Its overall parameters and configurations are similar to those of the above two-platform full cover laser CNC metal cutting machine. So you can refer to the above laser machine or contact us directly for more information. We will give you a detailed introduction or customized automatic cutting plan.

The tube metal laser cutting machine is a type of economical metal CNC machine. Only a small investment can bring you a large number of returns. Just as its name implies, this CNC laser machine is the laser cutter for metal tubes and pipes. It can also cut L-shaped, T-shaped, U-shaped, and H-shaped steel bars besides regular-shaped pipes.

The tube metal laser cutting machine also uses two automatic pneumatic chucks with stable and efficient operation. One key controls the chuck opening and clamping and it can automatically determine the center of the pipe. The chucks fix and rotate the pipe during the cutting process. And it can provide a large and constant clamping force, so even heavy pipes can be fixed tightly without loosening or sliding. Thus, it can guarantee cutting precision.

Tube laser metal cutting machines are small in size and occupy a small area, which can save the workshop area. What's more, it is simple in structure and easy to install. Its fast production speed can create value for you quickly.

Models of the tube fiber laser cutting machine

Model

Item |

T6160/T9160 |

T6220/T9220 |

T6350/T9350 |

| Tube shape |

Round/square/rectangular |

Round/square/rectangular |

Round/square/rectangular |

| Cutting range |

Round φ10-160mm

Square 10-110mm

Rectangular circumcircle φ≤160mm |

Round φ20-220mm

Square 20-150mm

Rectangular circumcircle φ≤220mm |

Round φ20-350mm

Square 20-245mm

Rectangular circumcircle φ≤350mm |

| Max. pipe length |

3m/6m |

3m/6m |

6m/9m |

| Positioning accuracy |

±0.03mm |

±0.03mm |

±0.03mm |

| Repositioning accuracy |

±0.02mm |

±0.02mm |

±0.02mm |

| Max. rotating speed of chuck |

130r/min |

130r/min |

140r/min |

| Max. Speed of chuck feeding |

90m/min |

90m/min |

120m/min |

| Support file |

IGS |

IGS |

IGS |

The above data are theoretical values obtained under strict processing conditions. In actual use, different processing environments and conditions may have different values. Please note that this metal laser cutter can only cut pipes, not plates. So if your job involves the cutting of plates, this metal laser machine may not be your best choice.

Video

Here is the video of our metal tube and pipe laser cutting machine. It shows the cutting process of round and square stainless steel pipes.

Differing from the above large working-size laser machines, the precision fiber laser cutting machine is designed with small working areas. We currently provide five sizes of precision laser cutting machines. They adopt the ball screw driving method in terms of the transmission system. The accuracy of the precision metal laser cutting machine can reach 0.03mm.

Advantages of the precision laser metal cutting machine include:

- The protective cover allows the operator to observe the processing from outside and protects the environment as well.

- A real-time monitoring and alarm system monitors the work status all the time to ensure safe operation. It will give alarms in case any problem occurs. This helps prevent and reduce the potential risks and increases troubleshooting efficiency.

- Multiple working sizes are optional to satisfy the metal cutting work of different sizes.

- You can choose an automatic focusing laser head, which can adjust the focus position automatically during the cutting process.

Models of the precision metal laser cutting machine

Model

Item |

6060Q |

9060Q |

9090Q |

1390Q |

1313Q |

| Work area |

605*605mm |

905m*605mm |

905*905mm |

1305*905mm |

1305*1305mm |

| Machine size |

2500*2250*1950mm |

| Bearing capacity |

70kg |

100kg |

140kg |

210kg |

300kg |

| Positioning accuracy |

0.03mm |

0.03mm |

0.03mm |

0.03mm |

0.03mm |

| Repositioning accuracy |

0.02mm |

0.02mm |

0.02mm |

0.02mm |

0.02mm |

| Laser |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

| Laser head |

Raytools |

Raytools |

Raytools |

Raytools |

Raytools |

| Focusing |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

| Lubrication |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

Auto/manual |

| Ball screw |

TBI |

TBI |

TBI |

TBI |

TBI |

| Guide rail |

T-win/HMI |

T-win/HMI |

T-win/HMI |

T-win/HMI |

T-win/HMI |

We can choose the precision metal laser machine parts and components of different brands or specifications according to customers' demands.

The coil fed metal laser machine optimizes the traditional processing method. And it upgrades the single cutting process to an integrated processing production line. The automatic and continuous feeding method realizes constant cutting production and improves equipment utilization, thus creating more value for users. If equipped with an exchange platform, work efficiency can be further improved.

This type of metal laser cutting machine is very suitable for cutting thinner metals, such as stainless steel, aluminum, etc. The thickness of the coiled metal sheets is between 0.8-2mm. It can achieve on-demand-based use of materials and realize better utilization. Moreover, this CNC laser machine can also feed materials while cutting, which greatly shortens the cutting time of parts.

Models of coil fed fiber laser sheet metal cutting machine

Model

Item |

1530FC |

1540FC |

1545FC |

| Work area |

1515*3030mm |

1515*4040mm |

1515*4545mm |

| Max. acceleration |

1.5G |

1.5G |

1.5G |

| Max. link speed |

140m/min |

140m/min |

140m/min |

| Positioning accuracy |

±0.05mm |

±0.05mm |

±0.05mm |

| Repositioning accuracy |

±0.03mm |

±0.03mm |

±0.03mm |

| Laser |

Raycus/GW/IPG |

Raycus/GW/IPG |

Raycus/GW/IPG |

| Laser power |

1-2kW |

1-2kW |

1-2kW |

| Coil material thickness |

0.8-2mm |

0.8-2mm |

0.8-2mm |

Advantages of coil fed laser metal cutting machine

- It can cut metal sheets continuously. The coiled metal sheet is fed to the sheet metal cutting machine automatically after being uncoiled and leveled.

- The whole process, from uncoiling, leveling, feeding, cutting, to discharging, is done automatically. This greatly improves work efficiency.

- Flexible production can respond to the changing production needs at any time. You only need to modify the design files on the software instead of changing the hardware structure of the machine when cutting other parts.

- The nesting software can optimize the cutting layout to maximize the utilization of the sheet metals. This also helps reduce the wastes and decline production costs.

Metal laser cutting machine price

The metal laser cutting machine price is affected by many factors. But compared to other steel cutting machines, the price of fiber laser machines is relatively higher. In short, you need to consider many aspects in order to know the laser metal cutting machine price. For instance, accessories, brands, services, machine configurations, etc.

Blue Elephant is committed to providing high-quality and inexpensive metal laser machines for users all over the world. There are many types of Blue Elephant laser machines with different prices. Even for the same type of metal laser cutter, different models will have price differences.

Metal laser cutting machine price range table

| Machine type |

Price range |

| Sheet metal laser cutting machine |

$15,000 - $50,000 |

| Tube and sheet fiber laser cutting machine |

$25,000 - $60,000 |

| Full cover sheet metal laser cutter |

$25,000 - $95,000 |

| Metal tube laser cutting machine |

$18,000 - $30,000 |

| Precision laser cutting machine |

$20,000 - $60,000 |

| Coil fed fiber laser sheet cutting machine |

$45,000 - $95,000 |

The above price range is for reference only. The specific metal cutting machine price depends on the specific specifications and configuration. Even if you use a different small part, it will cause a price difference.

Summary

The above text briefly introduces the types of metal laser cutting machines provided by Blue Elephant. At the same time, we have been actively researching and developing new models and functions. And we are committed to making Blue Elephant a world-class brand.

Metal laser cutting machines use a fiber laser to irradiate the metal surface to cause it to melt, thus cutting the metal parts out. Their common features include excellent precision, fast cutting speed, optimized design and layout, low production costs, saving labor costs, etc. However, different models of the metal laser cutting machine also have different focusing points. Some can achieve a single function, while some can realize multiple functions. So, the metal laser cutting machine price also varies greatly.

All the values in the above parameter tables are obtained from the rated value of certain parts and under extremely rigorous experiments. But they are not absolute. Different using environments and work conditions could generate different values. Therefore, these values are for reference only. If you are interested in any of the above metal laser cutting machine, don't hesitate to contact us. Our professional sales team will solve all your doubts.

We provide a double-platform sheet metal laser cutter to pursue highly effective loading and unloading. The two platforms adopt a high-and-low exchanging method, saving loading and unloading time. And the automatic exchange time is about 25s, which improves processing efficiency and saves labor costs. In addition, the driving motor is installed in front, leaving sufficient space for loading and unloading at the rear worktable. For more information about the exchange platform sheet metal laser cutter for sale, please click the picture or HERE.

We provide a double-platform sheet metal laser cutter to pursue highly effective loading and unloading. The two platforms adopt a high-and-low exchanging method, saving loading and unloading time. And the automatic exchange time is about 25s, which improves processing efficiency and saves labor costs. In addition, the driving motor is installed in front, leaving sufficient space for loading and unloading at the rear worktable. For more information about the exchange platform sheet metal laser cutter for sale, please click the picture or HERE. This metal sheet and tube CNC metal cutting machine can also equip an exchange platform the same as the sheet metal laser cutting machine. This can improve loading and unloading efficiency and save labor costs greatly. Click to know more details about the exchange platform sheet and tube metal laser cutting machine.

This metal sheet and tube CNC metal cutting machine can also equip an exchange platform the same as the sheet metal laser cutting machine. This can improve loading and unloading efficiency and save labor costs greatly. Click to know more details about the exchange platform sheet and tube metal laser cutting machine.