Positioning cylinder: Its role is positioning, not clamping fixed.

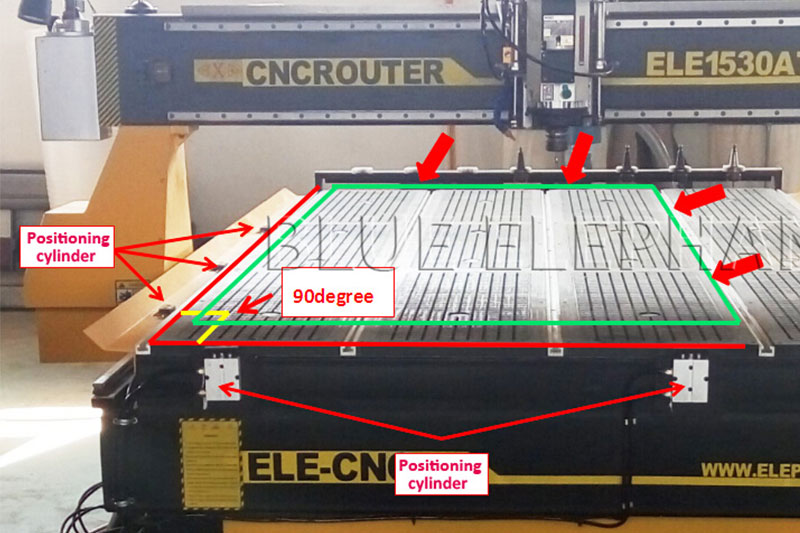

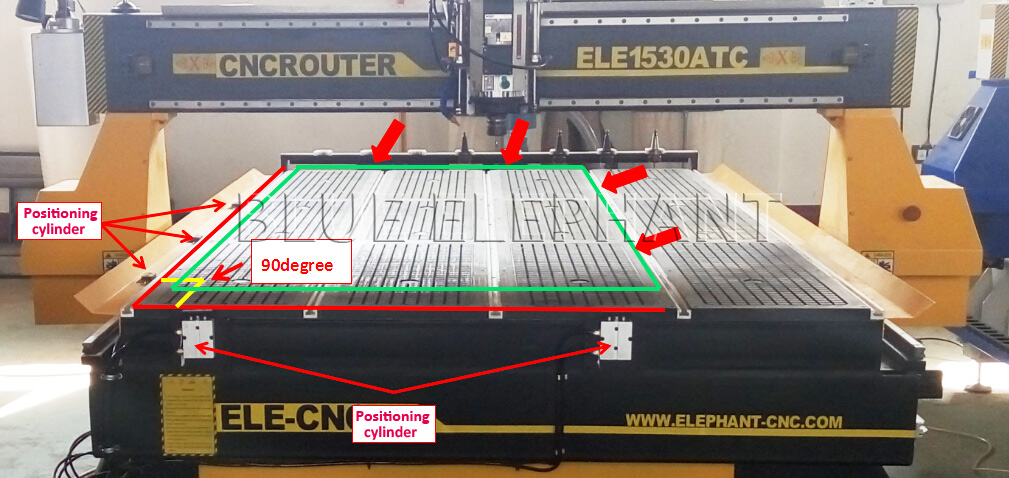

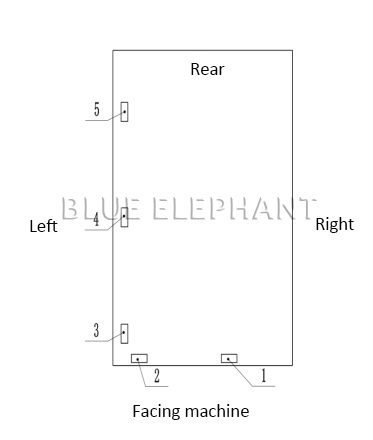

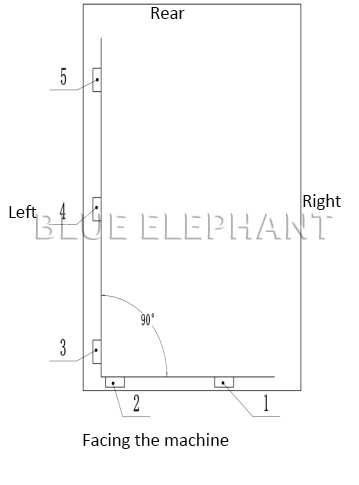

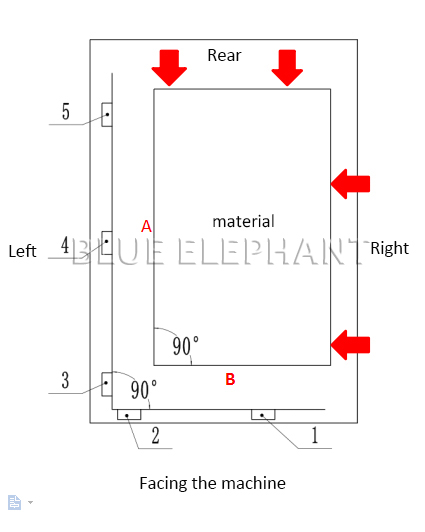

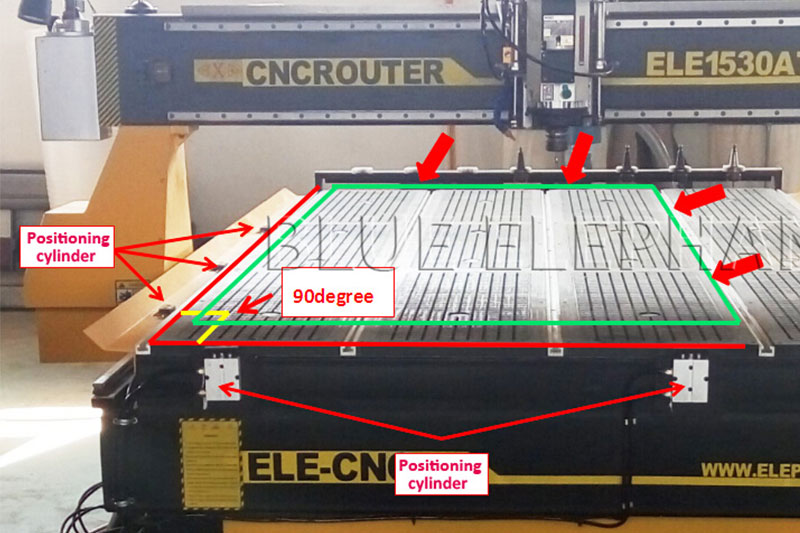

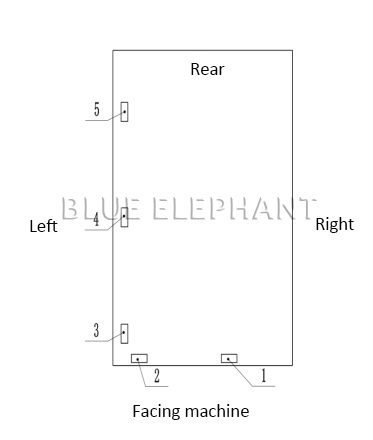

Generally we will layout two positioning cylinders in the front of the machine, layout three positioning cylinders on the left side of the machine.

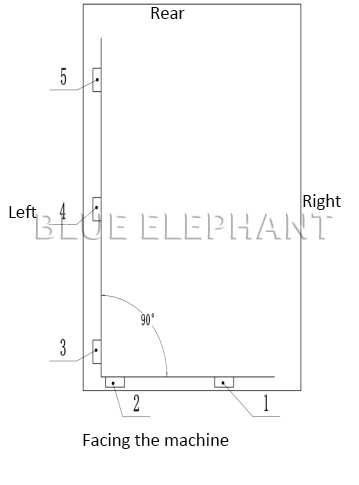

When the positioning cylinder rising will form a right angle.

As the picture show.

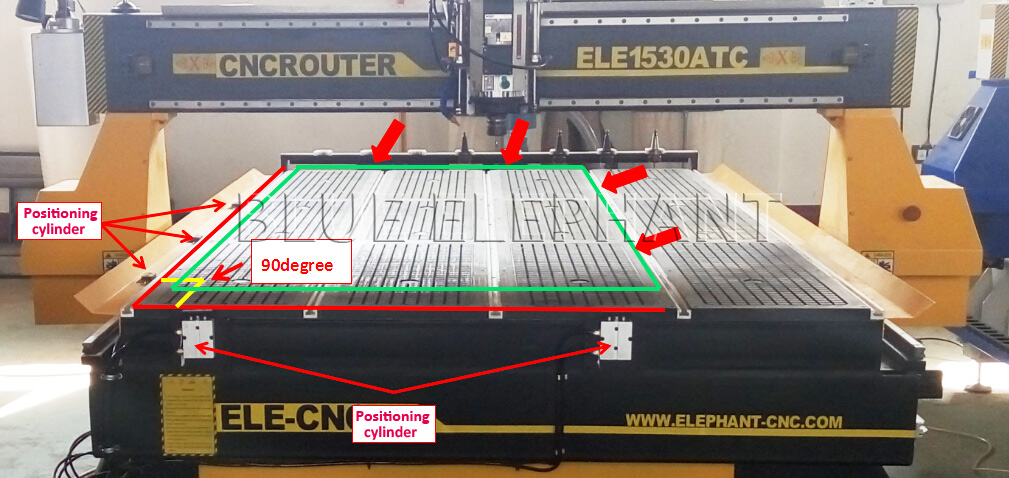

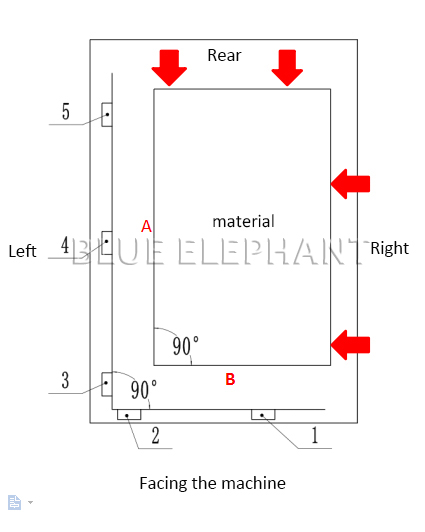

After the positioning cylinder rising, it will be 10mm higher than table surface. So that, the material could close to the cylinder rising directly.

- The positioning the cylinder rise.

- Push the workpiece in the direction of the arrow.

- Let the workpiece’s A&B side leaning on the positioning cylinder.

- Open the vacuum adsorption.

- Drop the positioning cylinder.

- Start to processing.

In fact, if you want to achieve better processing efficiency, or positioning cylinder is more suitable for customers who meet the following points:

a. Sheet: the materials are rule, such as the MDF, it has right angles and it’s thickness is uniform.

b.Batch processing.

PICTURE1: the positioning cylinder not raise

PICTURE2: the positioning cylinder raise

Advantages of the positioning cylinder:

- save the time to prevent repeat the tool sensor.

- save the time to let the material find the right position on the table surface. when we have the positioning cylinder, we only need to let the material firmly locate the positioning cylinder.

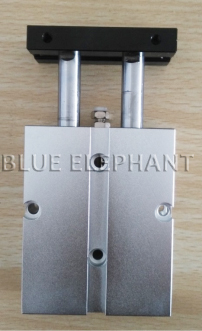

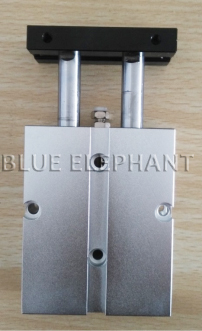

- The positioning cylinder has the compace structure and small size. Arranged on both sides of the table surface, do not take up valuable processing area.

- The positioning cylinder can be rise and fall, when we finish Positioning the material, it can fall directly, and hide below the table surface.

- And it won’t interfere with the tool and won’t hit the tool when is processing workpiece.