The panel CNC furniture production line realizes the file transfer between software and equipment. And it can also realize the transfer platform connection among the different CNC machines. It is a production method that enables the production of furniture to be intelligent and automated. This production method can not only save labor costs, save plates, but also improve processing efficiency and improve product quality. Therefore, CNC furniture production plans with different combinations are becoming more and more popular among furniture manufacturers.

We all know that traditional panel CNC furniture production is generally drawing by carpenter master-calculating and dismantling-row holes-sliding table saw cutting-row drilling holes-edge banding machine edge banding-trial assembly-packing. This production method has disadvantages such as high labor costs and low production efficiency. Therefore, traditional processing methods are no longer sufficient to meet people’s processing requirements. Instead, panel CNC furniture production lines with different combinations is becoming more and more popular.

The production cost and processing effect of different production line schemes are different. Choosing the CNC furniture production plans should be based on your own production conditions.

For example, if you need to process about 40 plates in 8 hours a day, you can choose 4 steps CNC nesting machine + edge banding machine + side hole machine.

If you want to process about 60-70 sheets in 8 hours a day, then you can choose a dual-process drilling package nesting CNC router + edge banding machine + side hole drilling machine.

Then if the processing plate is between 60 sheets to 100 sheets, then you should select the machining center with automatic load and unload platform + automatic edge banding machine + CNC six-sided drilling machine.

However, if the processing volume is more than 100 boards, you need to choose a fully automated panel furniture CNC cutting machine production line.

Today, Blue Elephant teaches you how to choose a suitable CNC furniture production plan for panel furniture according to your own production requirements?

The following are three different combinations and different configurations of the CNC furniture production plans. Let us take a look at which one is more suitable for you.

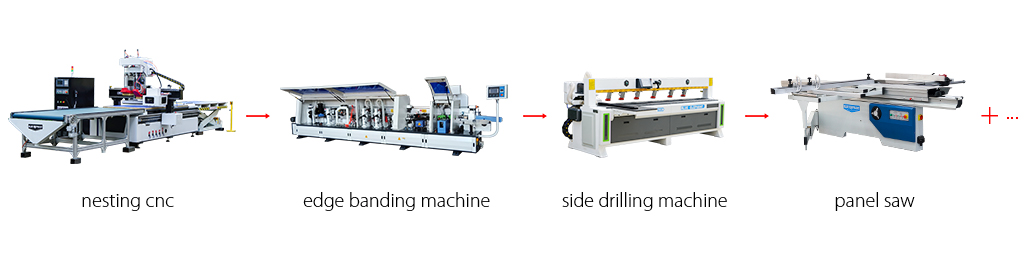

This CNC furniture production plan is an economical semi-automatic panel furniture production line. And it can process custom production of the whole house and can process 50 panels (standard size: 2.44*1.22 meters) per day in 8 hours. It is mainly including an automatic CNC nesting router machine, linear edge banding machine, side hole drilling machine, and panel saw, and other auxiliary processing equipment. The following are the processing effects achieved by each CNC machine in the CNC furniture production plan.

This is a set of standard CNC furniture production plans. It is mainly including a fully automatic CNC nesting machine, edge banding machine, five-sided drill / six-sided drilling machine if matched with five-sided drill, and other auxiliary equipment. It can be used for whole house custom production and can process more than 75 boards (standard size: 2.44*1.22 meters) every 8 hours. The following are the processing effects achieved by each machine in the production line plan.

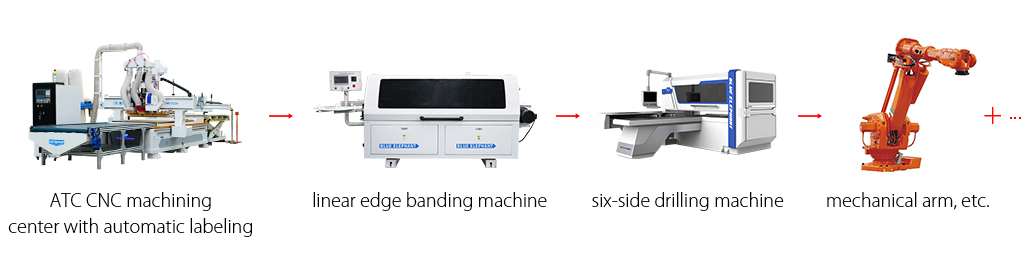

This is a high-end fully automated furniture production program. It consists of a fully automatic CNC cutting center, an edge banding machine, a six-sided drill, a mechanical arm, a semi-finished product buffer storage bin, and various types of power transmission lines. This panel furniture production line is a fully automatic panel furniture production line. More reasonable matching method: four sets of automatic labeling and cutting machines, two sets of automatic numerical control edge banding machines, four sets of through-type numerical control six-sided drills, one set of special-shaped plate automatic cutting center equipped with special-shaped edge banding machines, and numerical control six side drill, this kind of matching is high-yield and practical. Customized furniture manufacturers with lower budget and halved production capacity can choose a furniture production plan that includes two sets of fully automatic cutting machines, one CNC edge banding machine, and two sets of CNC six-sided drilling machines.

If the factory’s labor costs are extremely high, the total order volume is large, and the board categories are various and management is difficult, the front-end loading can be equipped with an intelligent three-dimensional warehousing system, and the back-end can be equipped with automatic intelligent sorting, packing and stacking.

For the plan of panel furniture production line, the related investment should not be simply compared with the investment in equipment costs, but should also be compared with the input-output ratio of the equipment, the number of supporting manpower, and the energy consumption during the operation of the equipment; through detailed data analysis, make sure it is suitable for your own factory equipment program.

With the rise of panel furniture, more and more custom-made furniture is selected for processing, making custom panel furniture factories more and more in need of mass production and automation. The panel furniture production line has become an urgent need for large furniture manufacturers. So how do choose a suitable panel furniture production line?

First, we must choose a reasonable panel furniture production line according to our own factory planning. If the company has only a few workers in the factory area, the main focus is on processing and customization, and the number of customers is not very large, it is generally recommended to choose a complete panel furniture production line, mainly to meet the production of panel furniture.

Secondly, we must choose a reasonable plan for the production line of panel furniture according to the company’s customer volume. If the company has been doing business for a long time, has a stable source of customers in the panel furniture market, and orders more customized furniture every day, you need to choose a panel furniture production line with high power and complete craftsmanship.

If you also have furniture production needs, if you don’t know how to choose a furniture production plan, please contact us. We can not only provide the above-mentioned three standard CNC furniture production programs, but we can also customize production plans for customers according to their processing needs. Trust us, we are professional.