BLUE ELEPHANT’S quality standard is set to be synchronized with Europe and America. All parts of the components are adopted international brands. With advanced processing and assembly crafts, with strict quality control, we are committed to providing users with stable and reliable equipment which can be used under long-term industrialization.

Forged countertops.

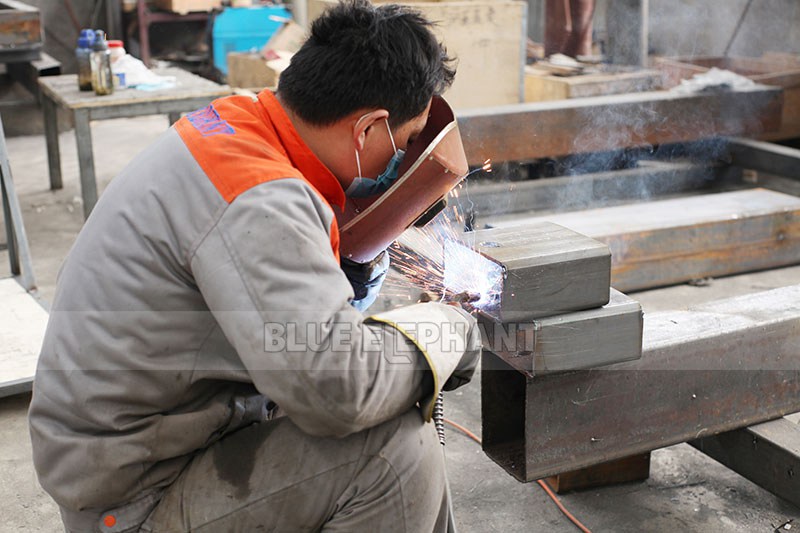

Strict annealing and other heat treatment processes to ensure the stability and rigidity of the whole bed structure. The entire machine is seamlessly welded and not easily deformed.

As you can see from the picture, the man is installing gear for machine. Generally speaking, helical rack on X axis and ball screw on Z axis. Sometimes, the Z axis is designed with double ball screw, and to make sure that the Z axis is much more powerful.

Fixing gantry is also an essential step when in the process of production.

Install the head of the machine

Troubleshooting

We can promise that only qualified machine can be delivered. Control and preciseness is embodied in the quality control system of our whole production lines. With strictly control system, we focus on reducing the rate of mistaking as low as possible. During the production stage, each machine would be inspected over one hundred times, and to simulate the most challenging working conditions, then conducted rigorous final verification tests. After that, machine would be packed for delivering to your hand.

Taiwan SYNTEC control system is safe and reliable. It can read G code quickly and have online simulation capabilities. At the same time, Taiwan SYNTEC control system can realize online monitoring function to ensure the efficient and safe processing. As can be seen from the image, our staff is debugging various functions of SYNTEC control system.

Fasten the wire rope and package it for shipment.

During the assembly stage, each machine would be inspected over 160 times to simulate the most challenging working conditions, then conducted rigorous final verification tests. We can promise that only qualified machine can be delivered.

During the assembly stage, each machine would be inspected over 160 times to simulate the most challenging working conditions, then conducted rigorous final verification tests. We can promise that only qualified machine can be delivered.

Welcome to visit our factory, and make contact with us.