The design and manufacture of customized panel furniture for the whole house is very flexible, including wardrobes, bookcases, wine cabinets, shoe cabinets, TV cabinets, walk-in cloakrooms, built-in wardrobes, and so on. Therefore, the whole hose customization becomes the preferred type of consumers. And it also drives the development of the whole house customized panel furniture production equipment. Among them, Blue Elephant has quickly occupied the national market of whole-house customized production equipment with its advantages of green environmental protection, professional design, industrialized production, and high-quality installation services.

Whole House Custom Process

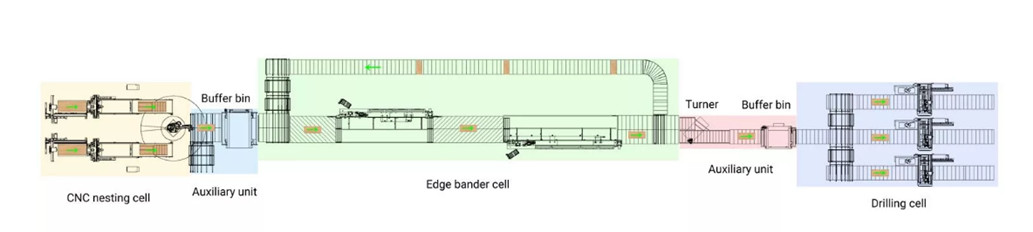

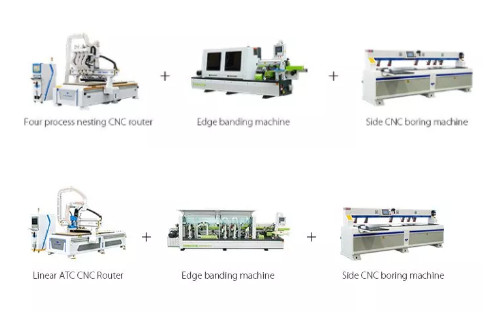

We should understand how the whole house custom production line is working. First of all, it is mainly composed of CNC cutting machine, drilling machine, edge banding machine, and auxiliary equipment. The CNC cutting machine can realize automatic grooving, automatic cutting, automatic material pushing, automatic tool changing, and automatic loading and unloading. In order to make the plate edge more neat and beautiful, the contribution of the edge banding machine is indispensable. The edge banding machine can perform milling, trimming, rough repairing, finishing, edge banding, and polishing, on the newly processed plates. In addition to the material cutting and edge sealing of the board, the punching process is also the top priority. Generally, the equipment used to realize the drilling process includes nesting CNC machine with drill package, PTP row drill machines, CNC six-sided drilling machine, etc. They are mainly responsible for punching and grooving the panels in multiple directions up, down, left, and right. If there are other more processes, such as polishing, laminating, etc., additional sanding machines and vacuum press machines can be added. And these processing units carry out different types of combinations according to the different process requirements of different customers. The following are some of the more common solutions, for reference only.

Blue Elephant Whole House Custom Production Equipment

Panel furniture production line equipment is the core product of Blue Elephant CNC. Since its establishment, Blue Elephant CNC has focused on the R&D and production of panel furniture production line equipment. The main products such as linear automatic tool change CNC nesting machine and four-process CNC nesting machine have undergone several generations of upgrades. In 2019, Blue Elephant independently developed and produced fully automatic edge banding machines, side hole drilling machines, and CNC six side drilling machines. At the same time, panel furniture production line such as intelligent labeling and nesting cell and unmanned fully automatic intelligent production workshop were also launched. Without reducing the function, it greatly reduces the number of equipment for a whole-house customized production line, helping customers save a lot of purchasing funds.

In addition, in the past two years, Blue Elephant has also successively developed and launched the whole house customized special production equipment such as quartz stone CNC machining center, 5-axis CNC machine, nesting CNC machine with saws, and door lock hole making machine. The quartz CNC stone machining center and the 5 axis processing center help the whole house custom manufacturers to realize the processing and production of panel furniture and quartz stone kitchen countertops. They satisfy customers' "one-stop" procurement of whole house custom production line. The "one-stop" procurement service not only provides customers with a wide range of product choices, but also helps customers solve complicated after-sales problems. No matter which equipment needs after-sales service, Blue Elephant CNC can quickly and timely send after-sales personnel to guide and serve customers. That means customers no longer need to connect with a large number of equipment suppliers.

Whole House Custom Solution

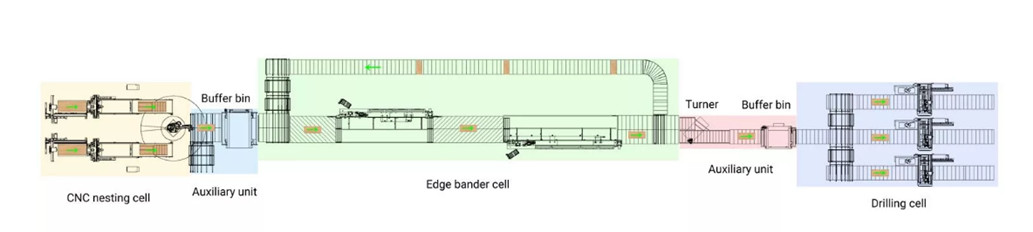

The whole house customized solution is combined by multiple units working together. Firstly, it has high automation, real-time presentation of production data. And only one person can be in charge of the entire production process, effectively reducing manual errors. Secondly, it has a variety of modes and can flexibly match the combination and quantity of each processing unit according to the site, process, production capacity, etc., so as to meet the production of different scales and processes. Even customized research and development and in-depth matching can be carried out according to the actual requirements of customers.

With more than 12-year industry experience and the good quality of CNC machines, Blue Elephant has upgraded its services and reconstructed its value. Provide a complete production line solution for the whole house custom to promote the industry advancement and generate revenue growth. Next, I will introduce three Blue Elephant whole house customization solutions. To provide new ideas for whole house custom business with different scale.

Entry-level whole house custom solution

The primary whole house customization solution is specially designed for small-scale whole house custom shop. It has the advantages of small footprint and affordable price. The following two entry schemes are the most popular.

Cutting unit

1. Four-process nesting CNC machine

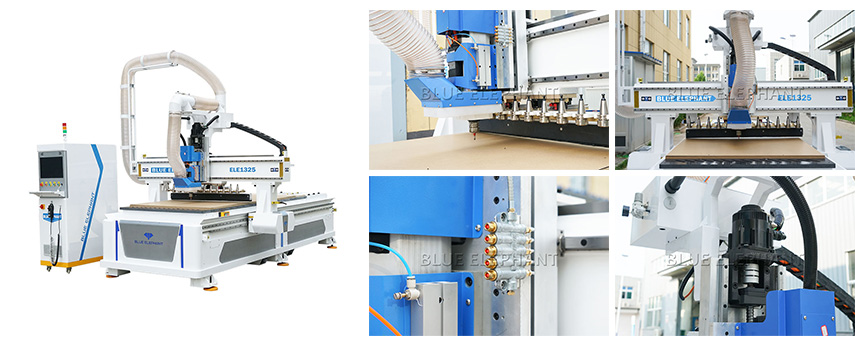

- The X-axis and Y-axis adopt helical racks, while the Z-axis adopts Taiwan TBI ball screw, which has high precision and durability.

- Steel mobile gantry has high precision, which can carry heavy weight, and is easy to operate.

- The three axes all adopt the Taiwan linear square rail, which has good stability, long service life, and high precision.

- 7 partitioned vacuum adsorption table is equipped with 6 positioning cylinders. And it also has a secondary dust removal effect. The embedded parts absorb the bottom plate, and the bottom plate can be quickly replaced without glue. It is more convenient to unload the material by the pushing device, which improves the productivity.

Video

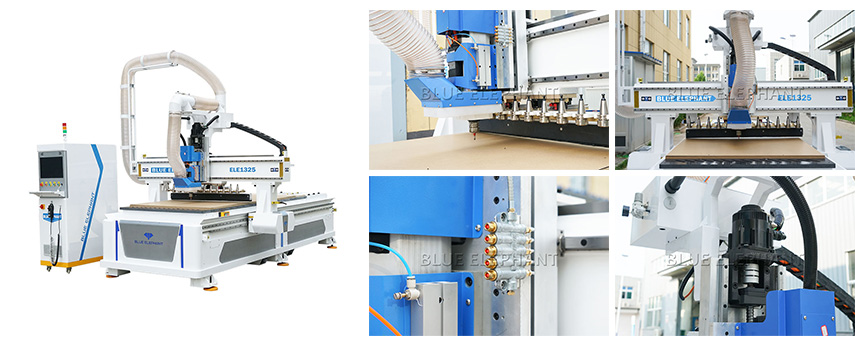

2. Linear ATC CNC nesting machine

- High-power 12 automatic tool changer saves tool change time and has high efficiency.

- Adopts a new large bed structure with high precision, large load capacity, and convenient operation.

- Taiwan Baoyuan system has good compatibility and is equipped with a handle for easy operation.

- The full vacuum table is divided into 7 areas will have stronger adsorption force, and no running board during processing.

- Equipped with soft and hard limits, which ensures high processing safety.

Automatic edge banding machine

Single head side hole machine

The single-head CNC side hole machine is an economical and practical equipment for punching horizontal holes in panel furniture. Combined with Blue Elephant intelligent software, it will get faster drilling speed and high drilling accuracy. The production can be completed by scanning the code, replacing the traditional sliding table saw and row drilling equipment, which greatly saves labor costs. Therefore, the side hole drilling machine is very suitable for small and medium panel furniture processing plants.

The whole process of entry-level whole house custom processing

Upgraded whole house custom solution

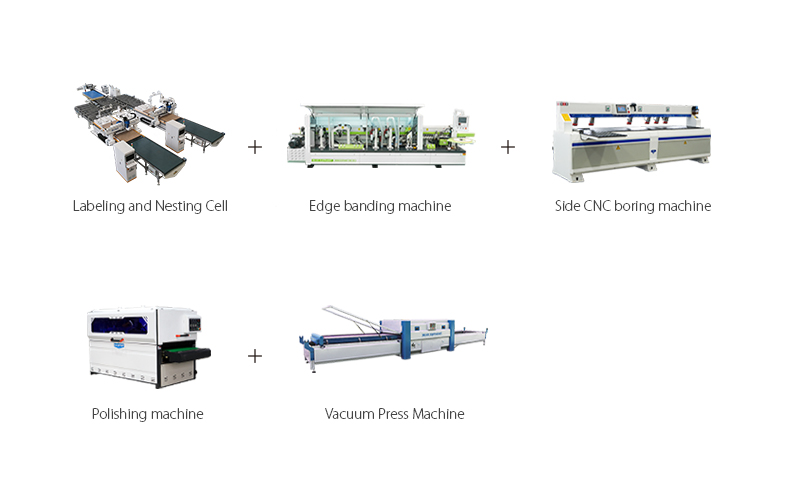

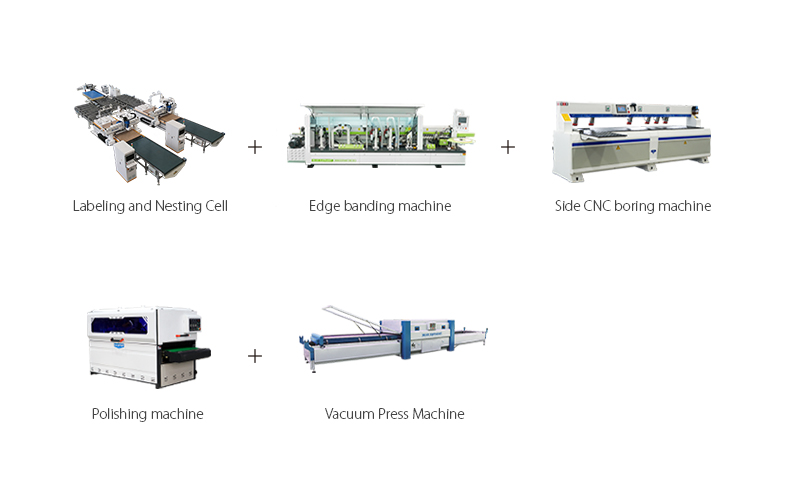

Compared with the primary whole house custom solution, this solution upgrades the cutting unit. One machine does more, with better precision and efficiency. In addition, a polishing unit and a pressing unit are additionally added to make the finished product more complete and beautiful.

1. Nesting CNC machine

Labeling and nesting unit

The intelligent two-in-one cutting unit integrates the automatic labeling CNC machine and two nesting CNC machines to realize uninterrupted production from loading to unloading. This cutting combination only needs one person to be on duty. The material loading and unloading are more accurate but with less labor. It can process 300 boards in 8 hours.

Video

Rear feeding computer panel saw

The maximum cutting size of the rear feeding computer beam saw can reach 4280*4280mm. And it can cut up to 150m in one minute. The driving system of the saw runs at high speed that can reach 200m/min. The movement is more precise, more stable, and the noise is lower. In addition, the intelligent feeding system adopts an independent pushing structure (double beams) to simultaneously carry out processing and loading, reducing waiting time and increasing sawing efficiency by 30%. At the same time, the two fingers of the manipulator are covered with rubber clamps to effectively avoid scratches on the sheet. The high-power variable-frequency motor can dynamically and intelligently adjust the speed according to the material and thickness of the board to achieve high cutting effect, low power consumption, and energy saving. The air-floating steel ball table prevents the sheet from being scratched and moves the sheet more easily. The self-developed control system checks the production progress in real time. So the production status is visualized. Moreover, it has multiple functions such as flexible data docking, task management, sawing editing, and database management. In addition, the configuration optimization software can optimize typesetting and realize efficient sawing.

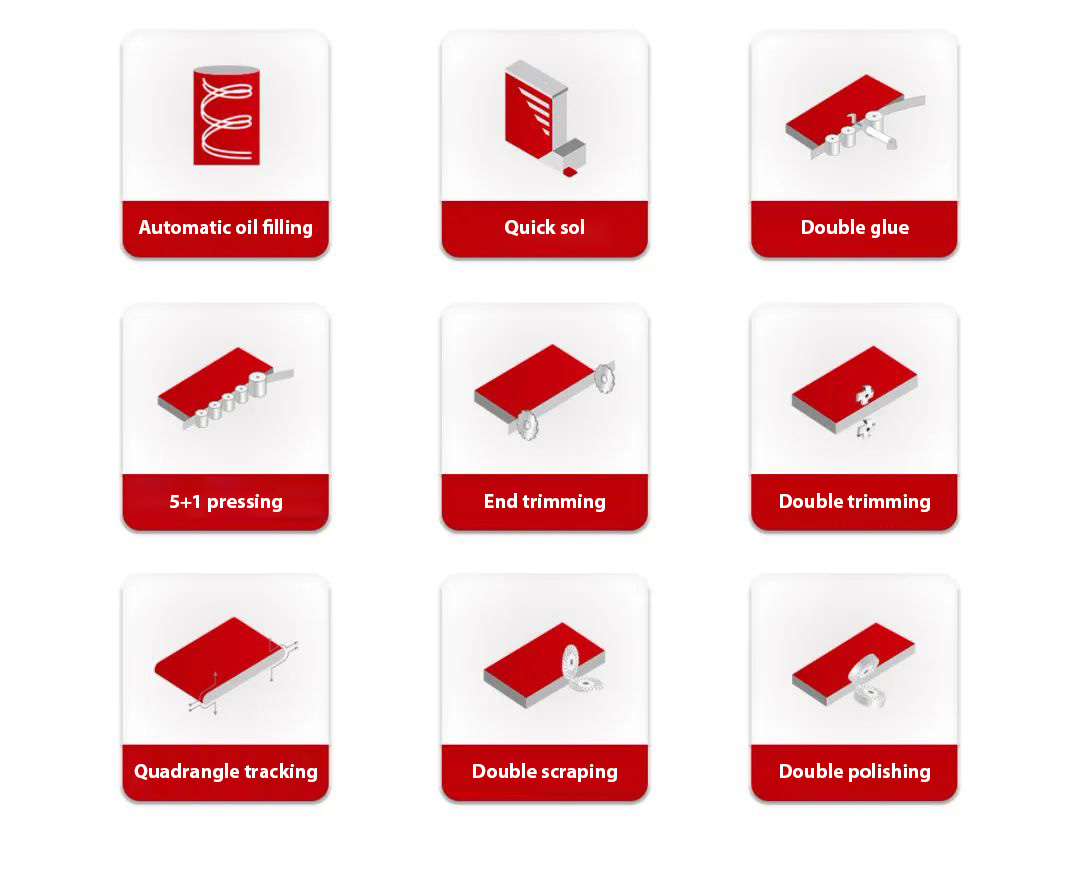

3. Fully automatic edge banding machine

① E-70

②

E-70JR

③

E-70J

④

E-70JDSR

4. Multi-head CNC side hole drilling machine

| Model |

Double head side drilling machine |

Three head side drilling machine |

| Picture |

|

|

| Size |

3300*1250*1300mm |

3600*1250*1300mm |

| Speed |

80m/min |

80m/min |

| Spindle |

2.2kw*2 |

2.2kw*2+saw |

5. Polishing machine

The main functionSanding machine is the surface processing equipment of woodworking. It is mainly used for rough grinding and primer polishing of wood products. And it can remove the burrs, marks, and roughness to obtain a smooth and flat surface. In addition, it also reduces the consumption of paint.

Technical Parameters

| Maximum processing width |

1300mm |

| Maximum processing length |

>400mm |

| Maximum processing thickness |

2-10mm |

| Power |

9.77kw |

| Size |

3100*1750*1850mm |

6. Press machine

The main functionVacuum press machine is used to absorb heated and plasticized PVC thermoplastic coil (PVC film), leather, veneer, etc. , photo frames and other products. It can be used to decorate various panel furniture, acoustics and decorative materials, especially suitable for embossed patterns on the surface.

Technical Parameters

| Working area |

2550*1300mm/2550*1150mm |

| Maximum processing height |

60mm |

| Fixed work stress |

≥-0.095Mpa |

| Power |

21-30kw |

| Maximum temperature |

185° |

High-end whole house custom solution

This solution uses the latest design and the most high-end production equipment of Blue Elephant. It is currently the most advanced, most complete, and most versatile whole house customization solution. It is especially suitable for professional whole house customization factories with mature skills, rich knowledge reserves, and large scale. And it is convenient for expansion of work and production.

1. Three machine connection

This kind of cutting unit adopts an automatic feeding device to connect three or more high-speed computer panel saws. It can automatically allocate the material according to the optimized CNC software. At the same time, it can realize the cutting of single board or stacked boards, which greatly improves the work efficiency up to 720pcs/h. So it is the preferred solution for large-scale cutting.

2. Automatic edge banding machine with PUR non-clean glue pot

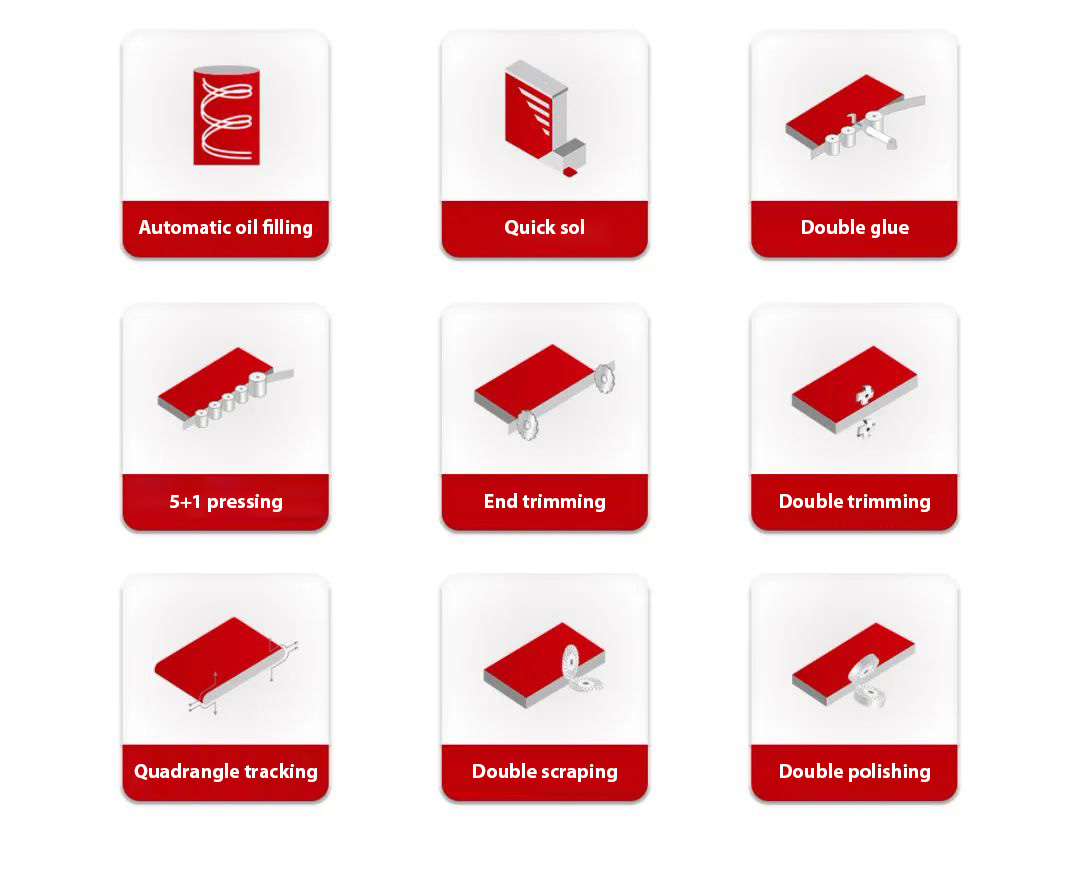

①Double milling: modify the defects such as corrugation marks, burrs or non-perpendicularity, so that the edge banding strip and the plate are more closely bonded. And the edge banding effect is improved.

②Automatic oil filling system: according to the machine running time, the guide rail is automatically filled with oil at regular intervals to ensure the normal operation of the machine.

③PUR no-clean glue pot: with quick-change melt glue, it is easy to replace. The liquid level of the glue pot is monitored by high-precision instruments, and the glue is automatically pre-melted and pumped. And the glue box has a large storage capacity, which can meet the glue supply for a long time and reduce the frequency of manual glue addition. The glue storage capacity reaches 12.5KG, and the pre-melt glue hopper capacity is 5KG. PUR port is reserved. So that two-color no-cleaning PUR can be selected to realize fast switching of different types of glue to meet production needs.

④Five-wheel pressing structure: 5 powerful pressing wheels with a diameter of 150mm. An additional rubber wheel is added to press the side bands strongly to improve the bonding effect of the side banding.

⑤Double trimming mechanism: fine trimming and rough trimming will cut off the excess edge band protruding from the upper and lower surfaces of the wooden board to make them even.

⑥ Polishing: eliminate excess glue marks and improve the finish of the board. Baking lights preheat the boards to improve the bonding effect of the edge banding.

3. Six-sided drill machine with double platform

The six-side drilling machine not only has the function of drilling six sides of the plate, but also can mill slots and special-shaped processing on the front and back sides of the plate. It has improved the traditional drilling process of the whole house customization industry, which is error-prone, labor-dependent, and low-efficiency. At present, with the change of customer demand, the six-sided drill can be divided into six-sided drilling machine with a drill package, six-sided driller with double drill packages, and six-sided drilling machine with double platforms. It only needs a QR code scanner to scan the barcode, and then the computer automatically reads the processing files. After the plate is placed in the six-sided drilling clamp, you can start processing by opening on the foot switch.

4. Subsidiary equipment

Whole House Customized Customer Cases

At present, Blue Elephant has more than 100 whole-house customized production solutions that have been implemented globally, providing customers with a large number of professional equipment choices and perfect pre-sales and after-sales services. Next, I will take the customer feedback from the three regions- Maldives, Malawi, and Qatar as examples to take you closer to the Blue Elephant whole house custom production line.

Whole house customization in Maldives

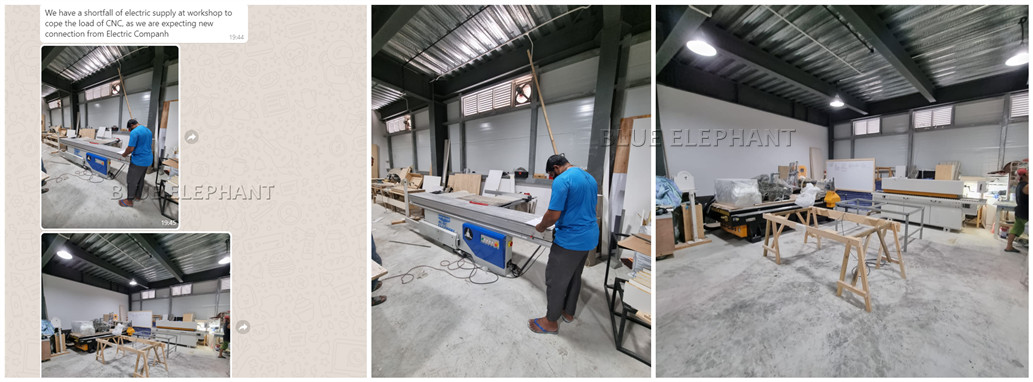

At the beginning of August 2021, our Maldives customer informed us that he had successfully received the Blue Elephant linear ATC CNC woodworking engraving machine, sliding table saw, and edge bander. After receiving the three CNC machines, he started to unpack and assemble the simple production line so that they can be put into production as soon as possible. Below are the feedback from Maldives customer on Whatsapp.

Whole house customization in Malawi

Two years ago, a customer from Malawi contacted us and said that he wanted to upgrade his equipment and improve his production line to expand his furniture manufacturing business. After understanding the customer's processing needs, we recommended the push panel saw, edge banding machine, and vacuum pressing machine to the customer. The customer thought that this was tailor-made for him, so he happily bought these three machines. After two years of use, the machines are intact and still functioning well. He was very satisfied with it and spoke highly of it.

Whole house customization in Qatar

Thanks to the Qatar customer for sharing the working video of the six-sided CNC woodworking drilling machine with us. This is our second cooperation. He had purchased a big 2040 ATC CNC cutting machine, a 3-axis CNC engraving machine, and an edge banding machine before. The machine is not only easy to install, but also very convenient to operate. After working for a long time, the customer thought that the quality of our machine was very good and the processing effect was unexpectedly amazing. So he bought this latest CNC six-sided driller from us again. We are very grateful to our customers for their trust and support. And we look forward to working with him again in the future.

Conclusion

At present, Blue Elephant CNC has almost realized the full coverage of the whole house customized production line products. Blue Elephant CNC panel furniture production line sell well at home and abroad, and have received wide acclaim. In the future, Blue Elephant CNC will continue to rely on strong research and development innovation capabilities, continue to improve various products of the whole house customized production line, and provide customers with better products and services. Welcome to visit!